The Ultimate Guide to Puff Print: From 3D Effects to Flawless Production

Introduction: More Than Just Ink, It’s an Experience

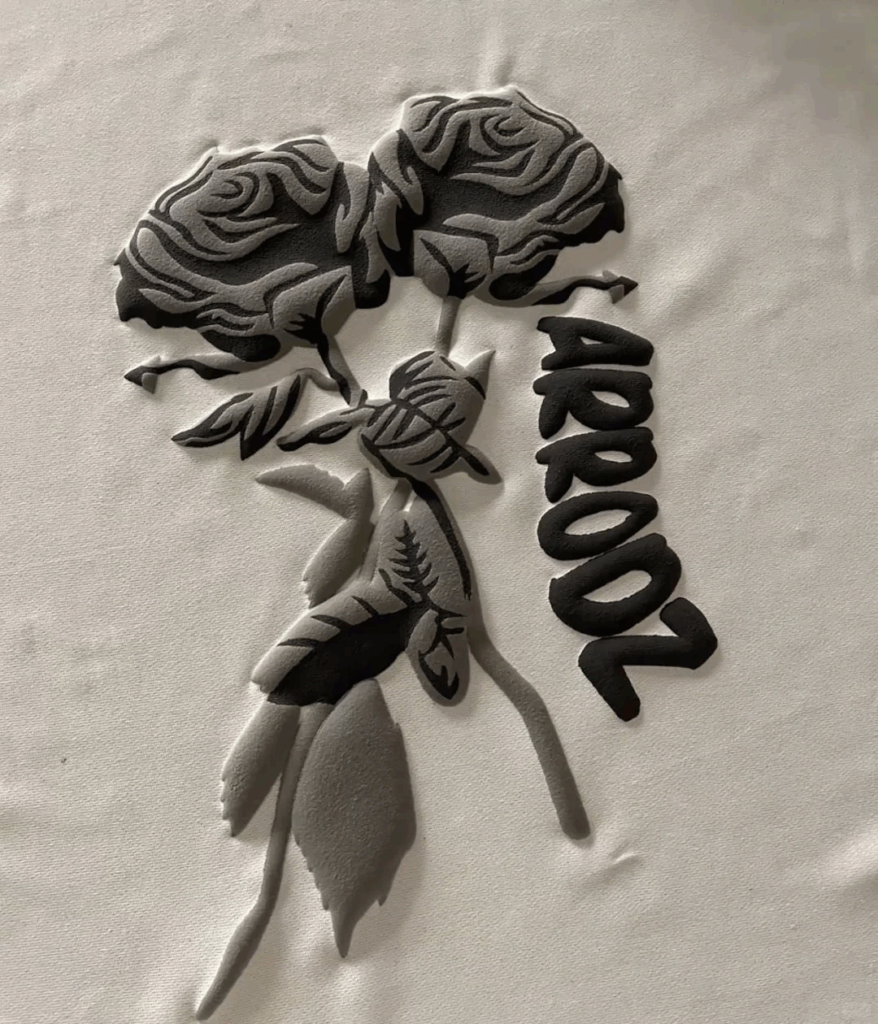

Puff printing, beyond a simple decoratiion process. It adds a tactile dimension to your clothes and turns even basic graphics into something you can reach out and touch.

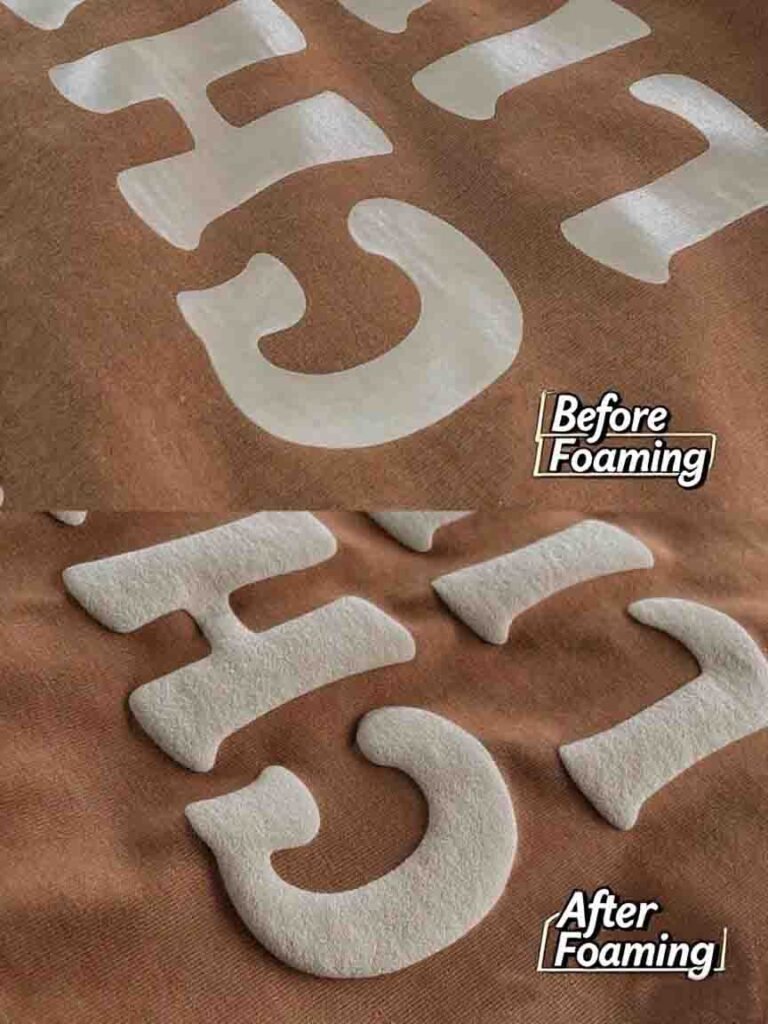

What is puff print? It is a unique screen printing process which uses plastisol ink which is made puffable with the aid of a foaming agent which is added to the ink. When properly heated, the ink will expand for a unique 3D layer and padded texture.

This palpability is part of what’s making it fashionable again. The style was big in the streetwear of the 1980s and the ’90s, and today’s brands are leveraging that nostalgia to produce clothes that feel at once old-school and high-end. Your creations will stand out in more ways than one!

The Science and Art Behind the "Puff": How Puff Printing Works

But knowing how to describe the process is important because it shows why precision is critical to quality results. How to make good ones, however, is a delicate balance of chemistry and heat.

2C: We’ve developed the signature puff effect through a meticulous step-by-step process making sure the print looks as good and lasts as long as possible. This is how a READY, puff print is done professionally:

- Ink Formulation: Everything starts with the ink. We mix standard plastisol ink with a special puff additive. The additive usually makes up 5% to 15% of the total weight, depending on how high we want the puff and what color we’re using. This ratio is key to getting the look clients want.

- Screen Preparation: Puff ink needs to be thicker on the garment than regular ink. To do this, we use screens with lower mesh counts (usually 60-110 mesh) that let more ink pass through to the fabric.

- Printing Application: The thickened ink gets applied to the garment through the prepared screen. This step requires steady pressure and speed to make sure the ink layer is even.

The Magic of Curing: This is when the transformation happens. The printed garment passes through a dryer. The ink must reach a temperature of 300-330°F (150-165°C) for the foaming agent to activate properly. When the agent reacts to heat, it expands upward, creating the “puff.” Getting the curing right is crucial – too little heat and the print washes out, too much and the puff collapses or gets brittle.

Pro Tip: ChengLin is ideal for brands looking for reliability, quality, and creativity in puff printing apparel production. Here’s a comprehensive look at why ChengLin should be your first choice for custom puff print manufacturing.

Weighing Your Options: The Pros and Cons of Puff Printing

Puff printing offers a unique look. However, it isn’t right for every design, and success depends on understanding both its strengths and limitations.

We believe in being honest, so here’s our breakdown to help you decide if it’s right for your brand.

Pros (Why Brands Love It)

- Unique 3D Visual & Tactile Appeal: This is the main benefit. Puff print makes designs “pop” off the fabric, creating a memorable look that people want to touch. The dimension it adds cannot be matched by flat prints.

- High Perceived Value: The texture and visual depth can make a simple t-shirt or hoodie seem more premium, allowing for higher prices. Customers see the added dimension as a special feature.

- Durability (When Done Right): A properly done puff print lasts surprisingly well. When correctly formulated and cured, the print flexes with the fabric and resists cracking for many wears.

Cons (What to Watch Out For)

- Limited Detail: The expansion process naturally softens edges. This makes puff print wrong for detailed designs with fine lines, small text, or sharp details, as they become blurry and hard to read.

- Color Matching Challenges: The puffing process adds air to the ink, which can lighten its color slightly. Getting an exact color match is harder than with standard inks and requires testing.

Specific Care Requirements: Clothes with puff prints need special care. High heat from dryers or irons can damage the print, making it flatten or melt. Customers need to know how to take care of their items.

Puff Printing Types We Manufacture

We specialize in customizing all types of puff printing for garments. Choose us for one-stop puff printing services. Here’s a look at what we offer:

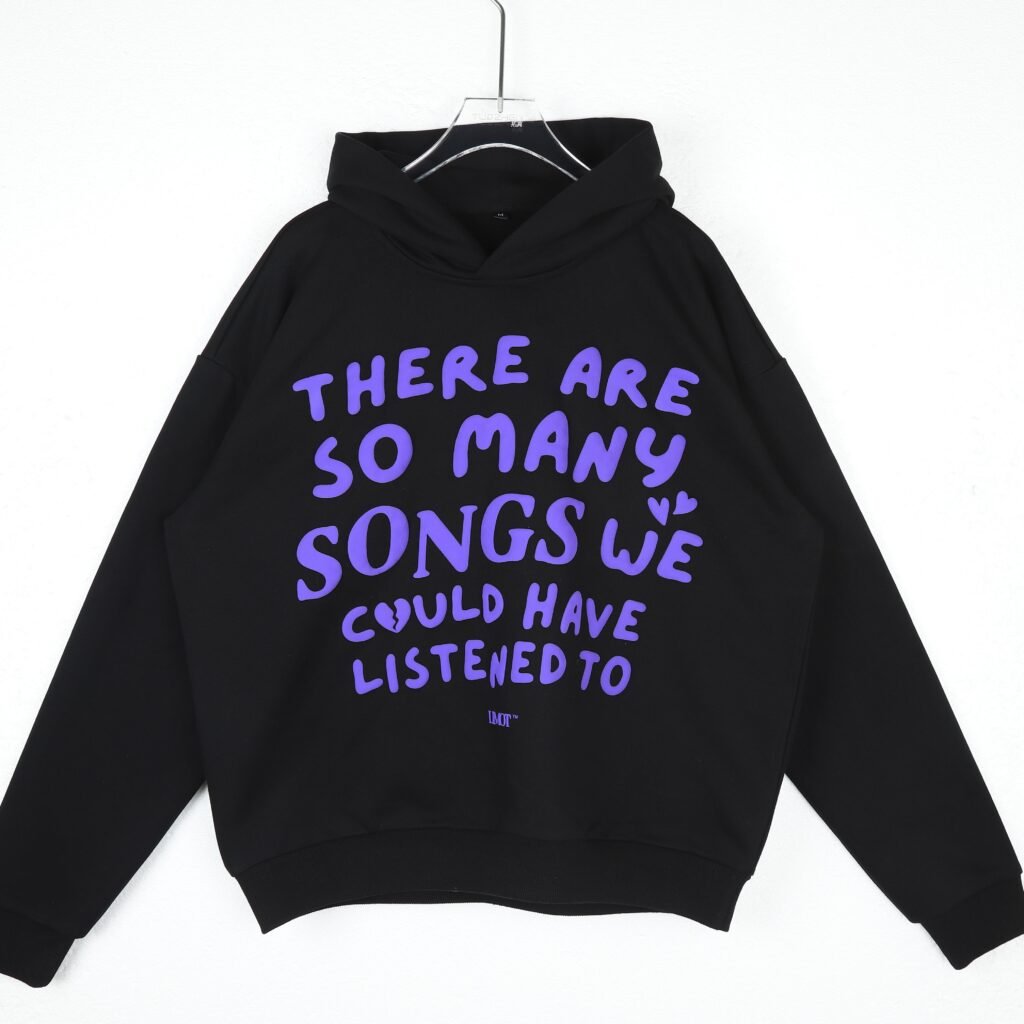

Puff Printing for Hoodies

Add bold texture and eye-catching dimension to your hoodies with puff printing. This technique creates a soft, raised 3D effect that brings logos, text, and graphics to life. Ideal for streetwear, casual collections, or standout branding, puff print on fleece or cotton hoodies gives your designs a unique tactile feel with lasting impact.

Puff Printing for Casual Pants

Elevate your casual pants with puff printing, the perfect way to add a bold, textured look to side stripes, logos, or statement graphics. The raised, 3D effect creates a unique tactile experience, making your designs stand out on cotton, fleece, or jersey fabrics — ideal for streetwear, loungewear, or fashion-forward collections.

Puff Printing for T-Shirts

Give your T-shirts a bold, elevated look with puff printing. This specialty technique adds a soft, raised texture to logos, artwork, and lettering — making designs pop with a 3D effect that’s perfect for streetwear, limited editions, or standout branding. Best suited for 100% cotton or cotton-blend tees for optimal print definition and durability.

Custom Puff Printing Services: Tailored for Your Brand’s Needs

For apparel brands, we offer a wide range of custom puff printing services and highly personalized printing solutions tailored to your specific branding requirements.

With our extensive experience in specialty inks, textured effects, garment compatibility, personalized labels, and custom packaging options, you can bring your unique design concepts to life with precision and creativity.

Our goal is to help you create distinctive products that resonate with your customers and elevate your brand identity. Understanding the importance of customization, we provide comprehensive puff printing solutions to meet all your brand’s specific needs — whether you’re producing custom t-shirts, hoodies, sweatshirts, or fashion-forward streetwear collections.

A Manufacturer's Guide: Optimizing Your Design for the Perfect Puff Print

With 27 years of garment production experience under our belts, we know the difference between an average puff print & a great one. The magic starts long before printing actually begins.

Planning your design well is the single most important factor to achieving a clean, long lasting, and great looking end result.

Artwork & Design Best Practices

To get the most from puff printing, your artwork needs to be created specifically for this technique.

- Go Bold: This technique works best with chunky design elements. Use thick lines, block letters, and large solid shapes. We suggest a minimum line thickness of at least 1.5mm (4-5 points) to ensure the puff effect shows up well and stays stable. Anything thinner might disappear or not puff correctly.

- Embrace Negative Space: The empty areas in your design matter just as much as the printed parts. Plenty of negative space helps define the design and prevents your artwork from expanding into a shapeless blob.

- Avoid Gradients and Photorealism: Puff printing uses single-tone, solid colors. It cannot reproduce color gradients, shading, or realistic photos. Trying to do so will result in a messy, poor-quality print.

Choosing the Right Fabrics

The material that you print on is as vital as the design. Not all materials can accept the heat and ink required for puff printing.

- Best Bets: Heavyweight 100% Cotton and thick Cotton-Poly Blends work great. Fabrics used for hoodies, sweatshirts, and premium t-shirts provide a stable, heat-resistant surface for the ink to stick to and expand on properly.

- Fabrics to Avoid: Stay away from thin garments or fabrics that stretch too much or are sensitive to heat. Materials like rayon, tri-blends, and performance polyester can warp or burn under the high heat of the curing dryer. The print may also crack on very stretchy fabrics. Understanding what your fabric is made of and how it handles heat helps avoid costly mistakes.

Puff Print vs. High-Density vs. 3D Embroidery: Choosing Your Dimensional Effect

Puff print is not the only way to bring some dimension to your clothes. Experienced brands frequently juxtapose it with high density printing and 3D embroidery. Each approach has a different look and feel, as well as cost.

The right decoration method for you will depend on your brand image, what product you are utilizing and what budget you have. Here, the primary distinctions are offered.

Feature | Puff Print | High-Density Printing | 3D (Puff) Embroidery |

Look & Feel | Soft, rounded, marshmallow-like, matte finish. | Sharp, crisp, “rubber-like” edges with a flat top. Can be glossy or matte. | Textured, stitched appearance with a very firm, high loft. |

Best For | Vintage/streetwear aesthetics, bold graphics, large typographic designs. | Modern, sleek logos, athletic wear, tech-inspired branding. | Premium branding on caps, beanies, patches, and heavy outerwear like jackets. |

Detail Capability | Low. Not suitable for fine lines or intricate details. | High. Can hold very sharp edges and relatively small details. | Moderate. Detail is limited by needle-and-thread construction. |

Cost / Complexity | Moderate. Requires special additives and precise curing. | High. Requires multiple layers of ink and very precise screen setup. | Highest. Time-intensive process with higher material and machine costs. |

Long-Lasting Style: How to Care for Your Puff Print Apparel

To keep the unique 3D effect looking good, proper care is essential. We provide these instructions with our products to help customers protect what they’ve bought.

High heat is the main enemy of puff print. Following these simple rules will keep the design looking crisp and raised for years.

- Washing: Turn the garment inside out before washing. Use a gentle cycle with cold water.

- Drying: For best results, hang dry. If you must use a machine, tumble dry on the lowest possible heat setting. Remove the garment quickly.

- Ironing: Never iron directly on the puff print. If you need to iron, turn the garment inside out and use low heat, avoiding the printed area completely.

- Harsh Chemicals: Avoid bleach and strong detergents, as they can damage the ink over time.

Following these proper garment care guidelines is the best way to maintain how your apparel looks and feels.

Partner with the Experts: Bringing Your Puff Print Vision to Life with ChengLin Clothing

The advice and best practices we’ve provided are based on our experience of 27 years in the apparel sector. We’re the experts in puff printing – helping brands navigate the pitfalls and realize strong, long-lasting high impact results that pop.

Here in ChengLin Clothing, we are not only a manufacturer. We’re a collaborator committed to getting every detail of your design right, from initial concept to finished production. We are with you every step of the way from assisting you in optimizing your artwork, selecting your fabric, and through production to ensure that your vision is perfection.

When you are looking to incorporate the distinct, tactile aspect of puff printing into your next release, put our experience to work for you..

Ready to start your project? Let’s talk.

- Direct Email: tesla@tuozhenclothing.com

- Phone Number: +8613713252727

- WhatsApp: +8613713252727

Real feedback from customers all over the world about ChengLin Manufacturer.

Communication & Production

How to Start Working with ChengLin Manufacturer?

3X

Your order is triple checked by our team prior to production and before shipment

Request a Free Quote & Consultation

Hit us up for a free quote. We’ll discuss your requirements — design, quantity, timing — and put a plan in place that works.

Submit Your Custom Design & Requirements

- Choosing puff printing Material

- Selecting the right Carft for the design

- Payment for samples

- Sample production after determining the color, size, and accessories of the sample

Receive Sample Prototypes for Approval

- Are the fabrics satisfactory?

- Does the craftsmanship live up to the design?

- Are there any changes that need to be made to the colors, sizes, and accessories?

- Details of large orders

Bulk Production & Delivery Process

- Payment of deposit for large orders

- Large Order Production Progress Inquiry

- Final payment upon completion of production

- Choose the right shipping method, pay the shipping fee, ship the goods

FAQ

What does "puff printing 720" refer to in garment decoration?

Puff printing 720 refers to a specialized screen printing technique that creates raised 3D textures, often utilizing 720 DPI resolution settings for optimal detail while maintaining the dimensional effect when the heat-activated foaming agent expands.

Why is the Gildan 2400 Ultra Cotton shirt popular for puff printing?

The Gildan 2400 Ultra Cotton long sleeve shirt is ideal for puff printing because its heavyweight 100% cotton fabric provides a stable surface that can withstand the high heat required for activating puff ink without warping or puckering.

What are the best design practices for successful puff printing in 2025?

For successful puff printing in 2025, use bold lines and chunky text, leave adequate spacing between elements to accommodate ink expansion, and consider strategic application by highlighting specific parts rather than entire designs.

What fabrics work best with puff printing techniques?

100% heavyweight cotton fabrics work excellently with puff printing, cotton/polyester blends (50/50) are good with proper testing, while 100% polyester and performance wear should be used cautiously due to heat sensitivity and dye migration risks.

How does puff printing differ from regular screen printing?

Puff printing differs from regular screen printing by incorporating a heat-reactive foaming agent into the ink that expands when heated to approximately 320°F (160°C), creating a raised 3D texture that adds both visual and tactile appeal to garments.

ChengLin Manufacturer Offer

ChengLin Manufacturer was created to provide helpful service, simple streamlined ordering & eco-friendly options. A company with transparent prices & ethics, a company that aims to create good things.

ChengLin Manufacturer Difference

ChengLin was created, to provide helpful service, simple streamlined ordering & eco-friendly options. A company with transparent prices & ethics, a company who aims to create good things.

Innovative Ideas

ChengLin is proud to be a leading partner in the promotional products + fashion industry. With unique ideas + out of the box printing methods.

We Stand Behind Our Work

Our main goal is to provide peace of mind so you can relax and have confidence that your job will come out exactly as you had imagined.

Quality Over Quantity

ChengLin believes in quality over quantity and we want our customers to feel the same way.

Dedicated Reps

Each account receives a dedicated rep who can be reached face to face by phone or via e-mail.

Long Lasting Relationships

We value all of our clients and aim to solidify long lasting & mutually beneficial relationships.