The Ultimate Guide to Plastisol Printing T-Shirts: Vibrant & Durable Results in 2025

Introduction: The Power Behind Vibrant, Lasting T-Shirt Designs

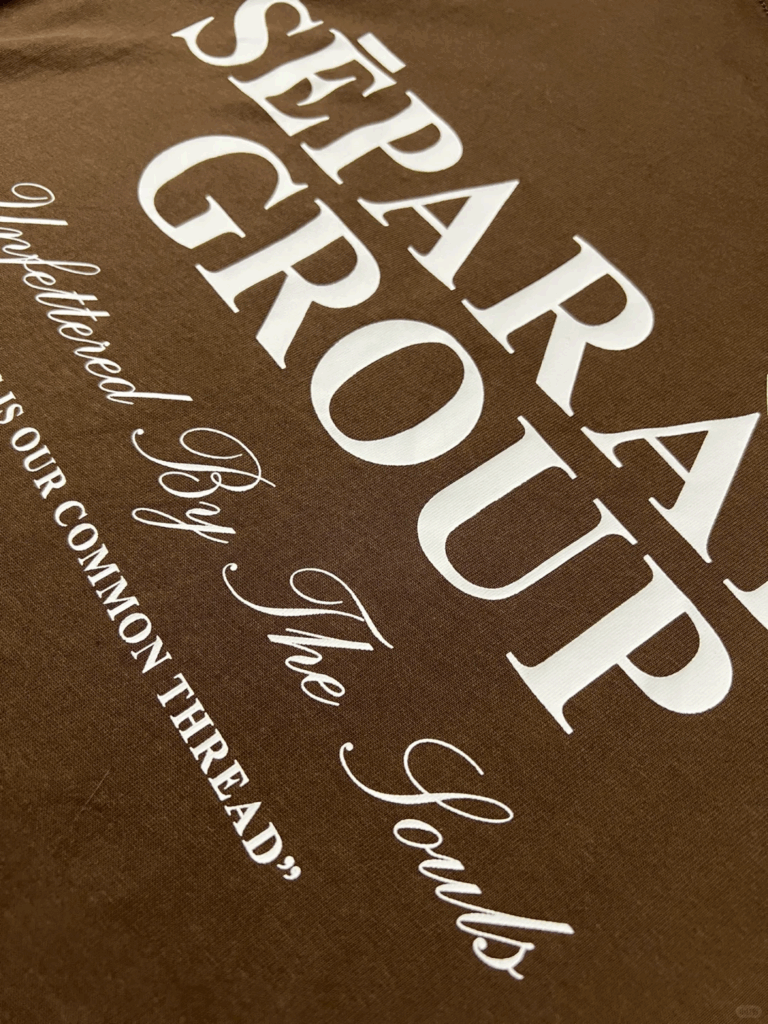

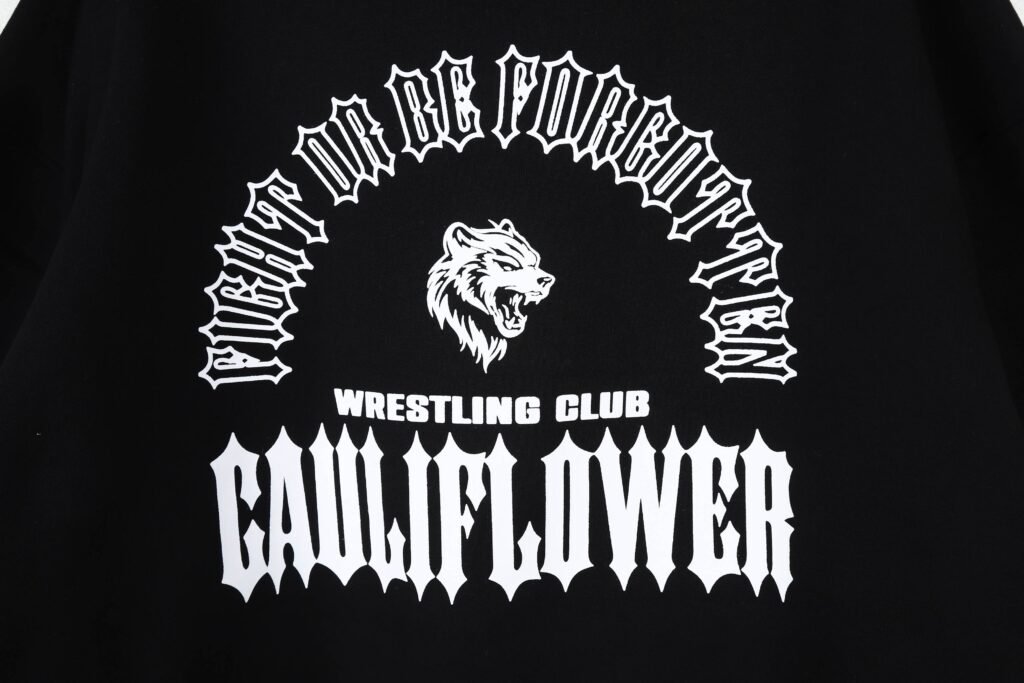

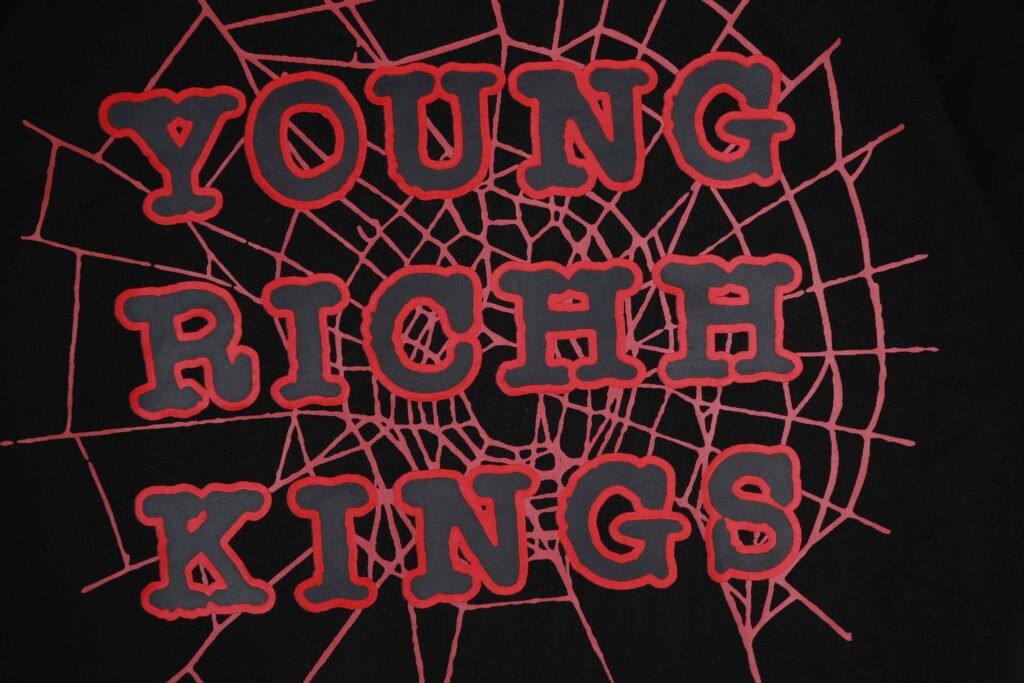

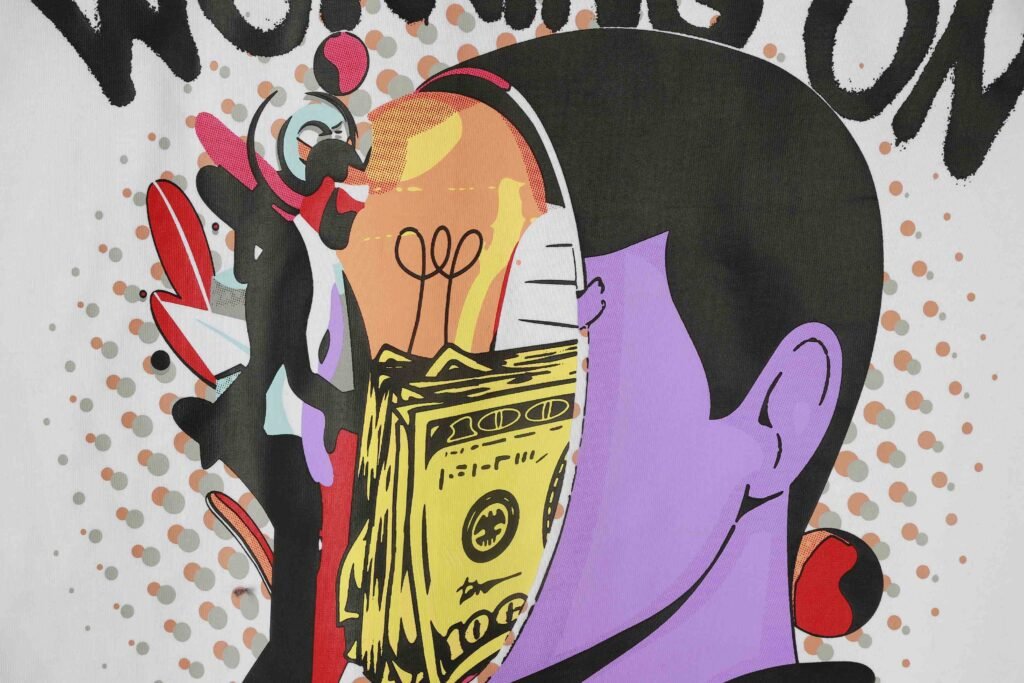

Picture your favorite band tee or that graphic shirt you have in an indestructible state after having been through dozens of washes. So, in all likelihood, the reason that it looks so defined, also an explanation as to how it lasts for a longer amount of time is plastisol printing.

It is a classical approach to create representatives shapes for iconic designs in the apparel history.

Plastisol Printing – Plastisol printing is a screen-printing process where solvent-based PVC inks are used and creates a design that is sharp, opaque, and long-lasting.

This post will show you how to do the entire process using what we’ve learned in 27 years. The team at Quartile will weigh it against other methods and answer the question if this is something your brand should consider.

The Plastisol Printing Process: A Look Inside the Factory

Plastisol printing is, at its core, simply a type of screen printing. The entire process — how a blueprint gets transformed into wearable merchandise?

After practising for almost 3 decades… this is how we deal with the process believe it or not.

- Design & Screen Preparation

First, your design is separated into individual colors. For each color, a fine mesh screen is coated with a light-sensitive material. The design is then “burned” onto it using UV light, creating a stencil that lets ink pass through only in the shape of your design. - Ink Mixing & Application

We mix the plastisol inks to match your brand’s exact colors. The thick, paint-like ink is applied to the top end of the prepared screen. - The Printing Stroke

The t-shirt is laid flat. A tool called a squeegee is pulled across the screen with firm, even pressure. This pushes the ink through the stencil onto the fabric. For designs with many colors, we repeat this process with a new screen for each color. - Curing: The Critical Final Step

This step matters most. The printed shirt travels through a conveyor dryer where it heats to about 320°F. This process bonds the ink to the fabric fibers. - Quality Control Check

Every piece gets inspected. We check color accuracy, alignment of colors, and proper curing to ensure the print won’t crack or peel.

You should also have a top design for your poll question, and this article on plastisol heat transfers is key. Printed on special paper This design can then be incorporated on a garment later by applying heat.

Pro Tip: ChengLin is ideal for brands seeking reliability, quality, and creativity in Plastisol Printing T-shirt production. Here’s why we’re your best choice for custom Plastisol-printed apparel.

The Great Debate: Plastisol vs. Water-Based vs. DTG

To create the ideal product for printing, you first need to select the best method of printing appropriate for your apparel brand. While there are some water-based inks in the fabric printing market, they do not compare with Plastisol and DTG printing. Each has unique strengths.

Now that we have understood the main differences, choose what fits your brand best.

Feature | Plastisol Ink | Water-Based Ink | |

Feel (Hand) | Sits on top of fabric, slightly thicker feel | Soaks into fabric, very soft, breathable | Soft, but can feel stiff on dark garments |

Vibrancy (on Darks) | Excellent, very opaque and bright | Less vibrant, requires underbase | Good, but may not match plastisol’s pop |

Durability | Extremely high; a well-cured print can last for years. As experienced printers often report, it can outlast the garment itself. | Good, but can fade faster than plastisol | Moderate, highly dependent on pretreatment |

Color Matching | Excellent, Pantone matching is precise | Good, but can be influenced by fabric color | Good, but relies on CMYK digital profiles |

Best for | Large runs, bold graphics, workwear | Premium/fashion apparel, vintage look | Small runs, complex photo-realistic designs |

Sustainability | PVC-based, less eco-friendly. This is part of the broader conversation about the impact of dyeing and finishing in the fashion industry. | More eco-friendly, water solvent-based | Water-based inks, but process has waste |

This will be best done based on what design you are trying to achieve, how easy you want it to feel and the volume of production.

Plastisol Printing T-Shirt Customization Options: For All Your Brand Needs

For apparel brands, we offer a variety of custom Plastisol printing T-shirt styles and highly personalized design options tailored to your specific branding requirements.

With our extensive selection of premium fabrics, expert printing craftsmanship, garment accessories, personalized labels, and custom packaging options, you can create the exact T-shirts you envision.

Our goal is to help you achieve a unique product that resonates with your customers and enhances your brand identity. Understanding the importance of customization, we, as a Plastisol Printing T-Shirt Manufacturer, provide comprehensive customization options to fulfill all your brand’s specific needs — whether you’re producing graphic tees, promotional shirts, or full custom collections.

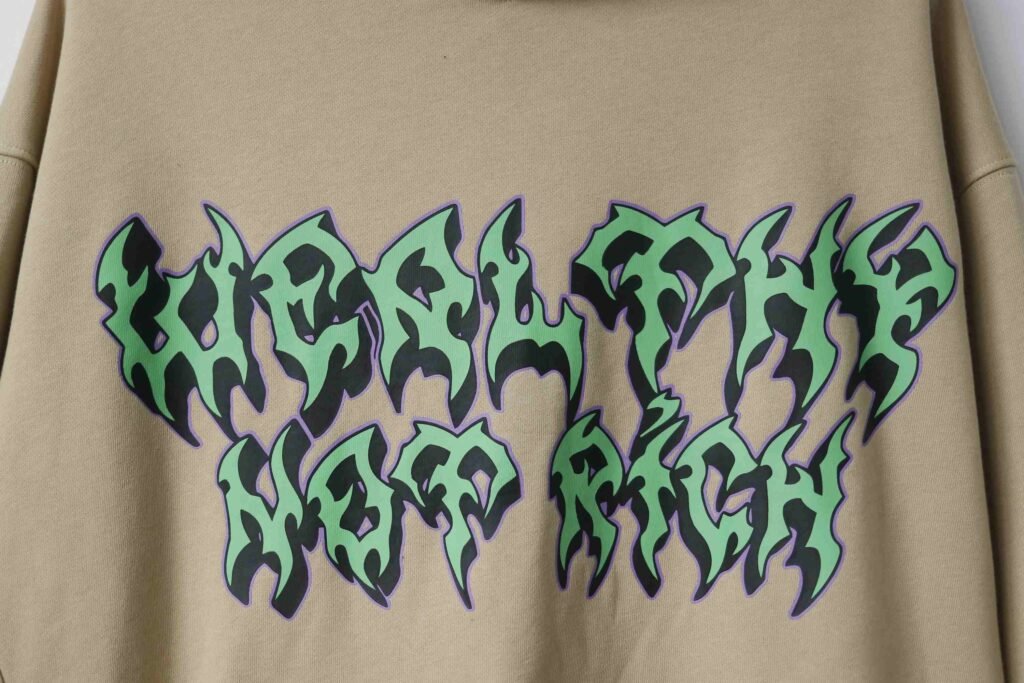

An Insider's Guide to Quality: Not All Plastisol Prints Are Equal

The biggest difference between an average print and a great one is you’ll be able to see and (if it’s textured) feel the details. When some one hears Plasticharge, remind them of the differences in ink cost vs production quality between cut rate plastisol prints vrs super premium plastisol prints.

Get revealed the secrets to quality plastisol printing.

- Proper Curing is Everything: This cannot be skipped. Under-cured ink will peel off after a few washes. Over-cured ink can feel brittle and stiff. A perfect print feels durable yet flexible.

- Pro Tip: The Stretch Test

Gently stretch the printed area about two-thirds of the shirt’s width. If the ink cracks and doesn’t spring back, it’s under-cured. A quality print will stretch with the fabric and return to normal. - The Importance of the Underbase: When printing on dark shirts, a good printer will first lay down a white ink layer. This base makes sure the top colors look bright and true.

- Ink Viscosity & Additives: Not all plastisol prints have to be thick. Expert printers use special additives to thin the ink, creating a softer feel without losing the bright colors that make plastisol famous. A print that is composed of PVC particles suspended in a plasticizer can be adjusted for different results.

- Screen Mesh Count: Just like a digital image has resolution, a screen has a mesh count. A low mesh count works for simple graphics, while a high mesh count is needed for detailed designs. A skilled printer picks the right screen for each job.

The Brand Owner's Decision Framework: Is Plastisol the Right Choice for Your T-Shirts?

So, in order to choose the right way of printing for your brand you should seek what style and business need you can match with a printing method. Ask yourself these questions.

What is your brand’s aesthetic?

- Go-To Choice for: Bold, graphic-heavy streetwear, band merchandise, promotional apparel, and corporate uniforms. If your brand needs bright, opaque graphics that pop, plastisol is the standard.

- Consider Alternatives for: Brands focused on a “lived-in” vintage feel, an ultra-soft premium feel, or a strong eco-friendly message. Water-based inks may work better for these styles.

What fabrics are you printing on?

- Go-To Choice for: 100% Cotton, Cotton/Poly Blends, fleece, and most standard t-shirt fabrics. Plastisol sticks very well to these materials, making it versatile. These pairings follow textile printing guidelines that often recommend specific ink-fabric matches for best results.

- Consider Alternatives for: Performance fabrics like 100% polyester or very thin, lightweight garments where a heavy plastisol print might feel out of place.

What is your order volume?

- Go-To Choice for: Medium to large production runs (typically 50+ units). The screen setup has fixed costs, so the price per unit becomes cheaper as the quantity increases. This makes it perfect for wholesale, tour merchandise, and large brand launches.

- Consider Alternatives for: One-off custom shirts, very small batches, or designs with many colors. DTG is more cost-effective for single pieces or small orders.

Partner with the Experts: Achieving Flawless Plastisol Prints with ChengLin Clothing

T-shirt printing is complicated and you really need not face this trouble alone. A good final product is a skill of your manufacturer partner.

We have 27 years of experience making clothes, so we at ChengLin Clothing are confident that our plastisol printing is the best. We know the ins and outs of everything from color matching to making sure each garment is cured to perfection – sending you the highest quality possible.

Our strong commitment to quality control means we handle every step with care. We work with brands to find the perfect printing solution for your vision.

We’re not just a factory; we are your production partner.

Ready to bring your designs to life with vibrant, durable plastisol prints?

Contact our expert team at ChengLin Clothing to start your project.

- ● Direct Email: tesla@tuozhenclothing.com

- ● Phone Number: +8613713252727

- ● WhatsApp: +8613713252727

Conclusion: Your Final Takeaway on Plastisol Printing

There is a reason why plastisol printing is considered to be one of the primary and most trusted principle in t-shirt industry. 5 business benefits in plastisol screen printing Plastisol screen Printing Business effect #1: Easy to print. Featuring unrivaled permanence, superb color saturation; all combined with extensive versatility when used on facrics of your choice.

Let’s recap the essentials:

- Vibrancy & Durability: Its key strength is producing bright, opaque graphics that last.

- Versatility: It’s a reliable choice for cotton, blends, and bold designs.

- Quality is Key: The final result depends entirely on the printer’s expertise in curing, underbasing, and ink management.

Over to you With a little knowledge of the elements that comprise a premium print, now you can go forth and wisely purchase. It is empowering to be able to quantify quality and determine precisely with whom should you align in order to build a great apparel brand.

Real feedback from customers all over the world about ChengLin Manufacturer.

Communication & Production

How to Start Working with Plastisol Printing T-Shirts Manufacturer?

3X

Your order is triple checked by our team prior to production and before shipment

Request a Free Quote & Consultation

Hit us up for a free quote. We’ll discuss your requirements — design, quantity, timing — and put a plan in place that works.

Submit Your Custom Design & Requirements

- Choosing Plastisol Printing T-Shirts Material

- Selecting the right Carft for the design

- Payment for samples

- Sample production after determining the color, size, and accessories of the sample

Receive Sample Prototypes for Approval

- Are the fabrics satisfactory?

- Does the craftsmanship live up to the design?

- Are there any changes that need to be made to the colors, sizes, and accessories?

- Details of large orders

Bulk Production & Delivery Process

- Payment of deposit for large orders

- Large Order Production Progress Inquiry

- Final payment upon completion of production

- Choose the right shipping method, pay the shipping fee, ship the goods

FAQ

What is plastisol printing and why is it popular for t-shirts?

Plastisol printing is a screen printing method using PVC-based ink that sits on top of fabric, creating crisp, opaque, and highly durable designs. It’s popular because it produces vibrant colors that last for years, even after countless washes.

How does plastisol printing compare to water-based printing and DTG?

Plastisol ink offers excellent vibrancy and durability but sits on top of fabric. Water-based ink feels softer as it soaks into fabric but is less vibrant. DTG works well for small runs and complex designs but may not match plastisol’s durability or color pop.

What types of t-shirts work best with plastisol printing?

Plastisol printing works excellently on 100% cotton, cotton/poly blends, fleece, and most standard t-shirt fabrics. It’s less ideal for performance fabrics like 100% polyester or very thin garments.

How can I identify a high-quality plastisol print on t-shirts?

A high-quality plastisol print should feel durable yet flexible, pass the stretch test (stretch without cracking), have bright colors (especially on dark shirts), and maintain its appearance after multiple washes.

Is plastisol printing cost-effective for small t-shirt orders in 2025?

Plastisol printing is most cost-effective for medium to large runs (50+ units) due to setup costs. For one-offs or very small batches, DTG printing is typically more economical in 2025.

Plastisol Printing T-Shirts Manufacturer Offer

ChengLin Plastisol Printing T-Shirts Manufacturer was created to provide helpful service, simple streamlined ordering & eco-friendly options. A company with transparent prices & ethics, a company that aims to create good things.

ChengLin Activewear Manufacturer Difference

ChengLin was created, to provide helpful service, simple streamlined ordering & eco-friendly options. A company with transparent prices & ethics, a company who aims to create good things.

Innovative Ideas

ChengLin is proud to be a leading partner in the promotional products + fashion industry. With unique ideas + out of the box printing methods.

We Stand Behind Our Work

Our main goal is to provide peace of mind so you can relax and have confidence that your job will come out exactly as you had imagined.

Quality Over Quantity

ChengLin believes in quality over quantity and we want our customers to feel the same way.

Dedicated Reps

Each account receives a dedicated rep who can be reached face to face by phone or via e-mail.

Long Lasting Relationships

We value all of our clients and aim to solidify long lasting & mutually beneficial relationships.