The Ultimate Guide to High Density Print Shirts: From Technique to Production

Introduction: What Makes a High Density Print Shirt Stand Out?

When it comes to custom apparel, a high density print shirt makes a loud statement. Brands are able to move out of stale 2D images. This method converts a basic logo into the tangible and visible thing that customers.so it can be seen.

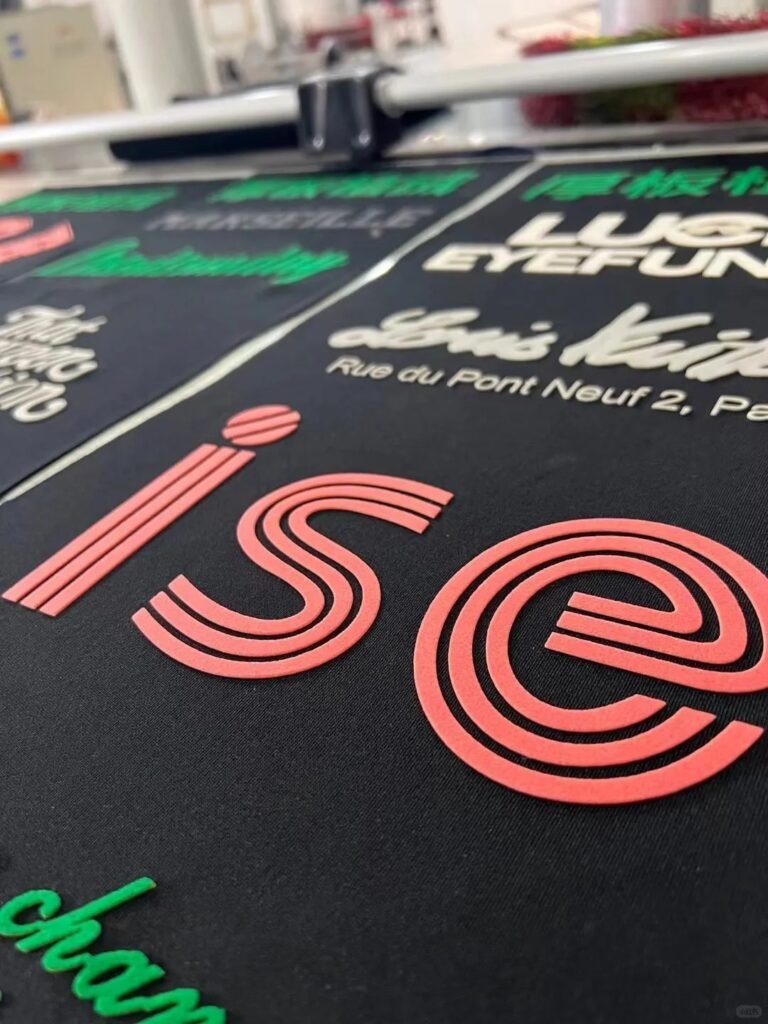

Beyond Flat Ink: A Definition

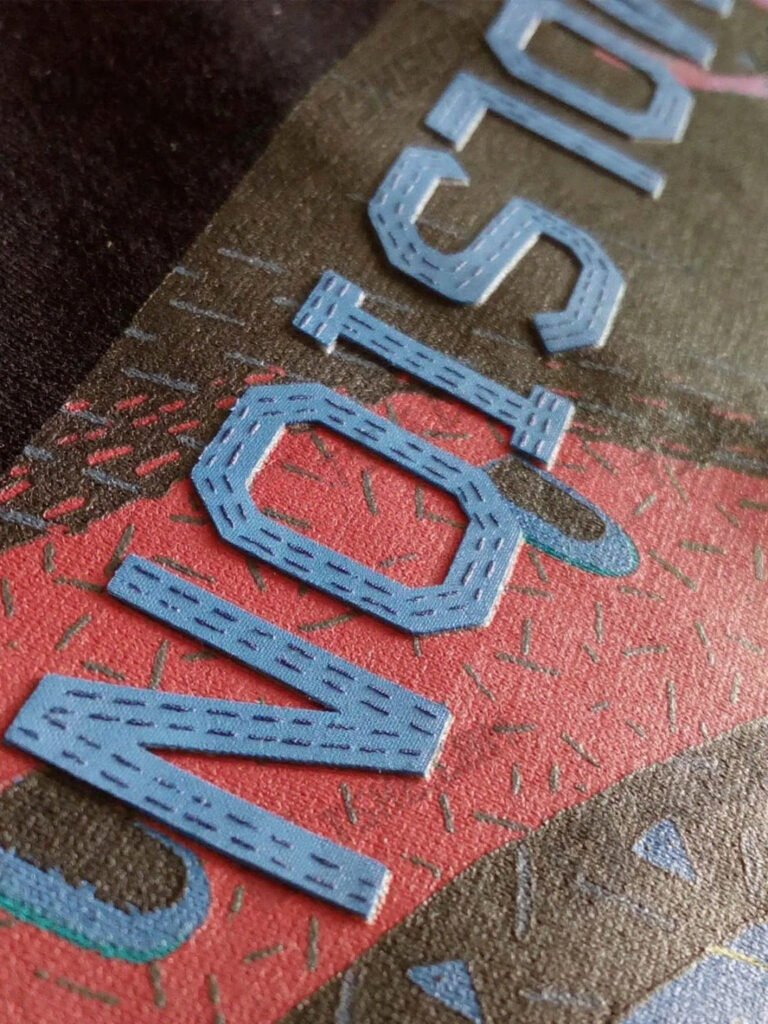

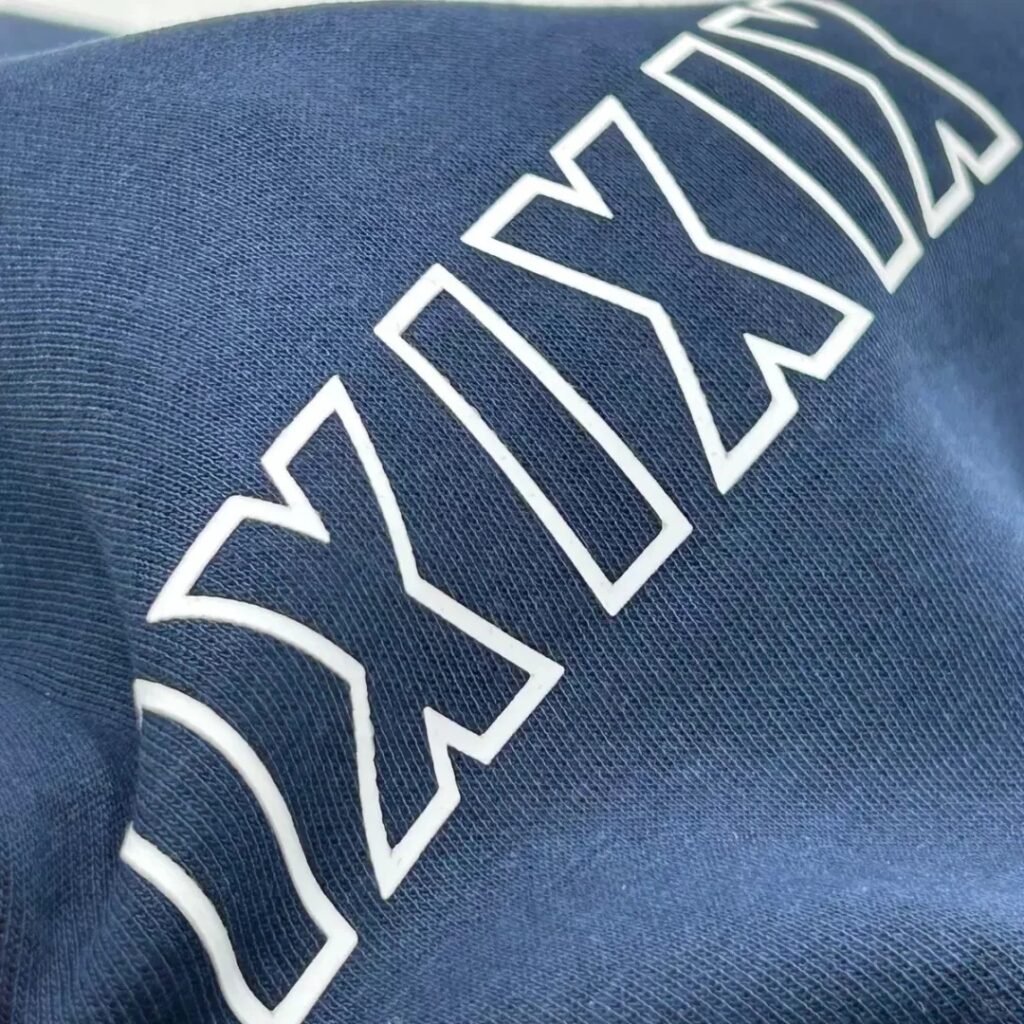

On the fabric, it has a 3D, embossed appearance because of high density printing. We will build up the layers for the material using special ink. The outcome is a part with crisp contouring and leather-feeling texture.

The same thing with the difference between a sticker and Manufacturer emblems. This tactile dimension that is impossible in standard printing. This method places the depth on the garment itself.

First Impressions Matter

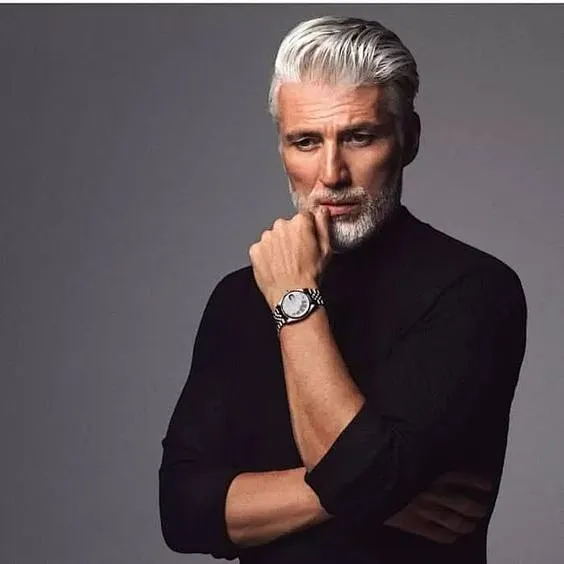

High density printing is a choice for brands to make their products look higher in value. This is a style that colors the logos to mimic popping off of the shirt. This is pretty impactful for visual and touch-based interactions.

The luxurious investment also signals an attention to detail. High density print shirt that makes logos or simple text architectural graphics stand out and be remembered.

The Art and Science of the High Density Process

Bottom line, high density print is painstaking to get perfect. It requires a special material and precise techniques outside of your standard screen print. It is by understanding this workflow that you appreciate the quality of the final product.

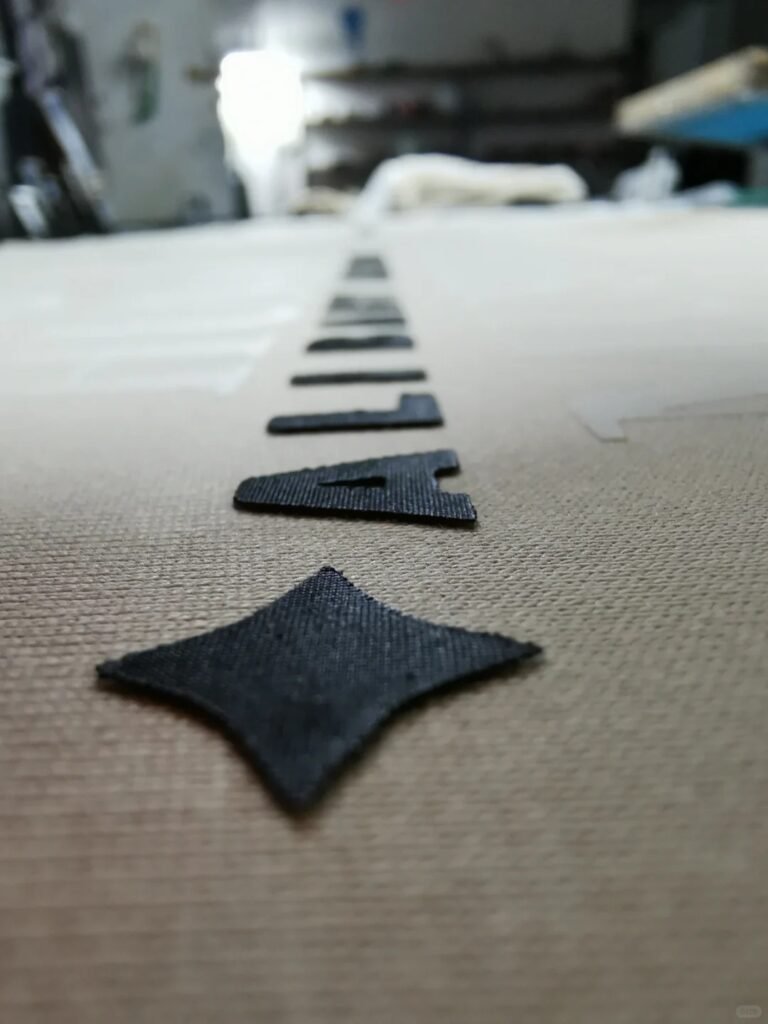

It Starts with the Screen

The base is a specialty, ultra-high-durability mesh stencil. The interior of this stencil holds the ink for height (mold) Thickness is {part} height //amount of control over how much the final print will stand proud

This control ensures uniformity of all shirts in a run.

The Specialty Ink

Printing:High density printing with paste like ink and high yeast ink. This special ink does not expand outward, but instead grows upward — like building blocks stacking up to grow further. The ink has to be designed so that it can print sharp edges (and I do mean truly SHARP) yet remain flexible enough not to crack.

Though based on basic principles of screen printing, such a technique requires materials not found in general screen-printing applications to obtain its 3D effect.

Layer by Layer: The Printing and Curing Cycle

That 3D effect is created step by step. And it is by meticulously layering ink over other layers. This is what makes it a premium print process.

- Ink Application: A squeegee pushes the first layer of thick ink through the stencil onto the fabric.

- Flashing: The shirt is briefly heated. This makes the ink dry to touch but not fully hardened.

- Stacking: The process repeats. Another ink layer goes on top of the first, and the shirt is heated again. This continues until the design reaches the right height.

- Final Cure: Once the last layer is applied, the entire shirt passes through a dryer at a specific temperature. This permanently bonds the ink to the fabric.

However, in our 27 years of experience we have eliminated this process to avoid cracking! This step is important as you want your print to stay crisp and sharp after washing.

Pro Tip: ChengLin is ideal for brands seeking reliability, quality, and creativity in high density print shirt manufacturing. Here’s a comprehensive look at why ChengLin should be your first choice for custom high density print shirt production.

High Density vs. Puff Print: A Head-to-Head Comparison

For any brands looking for a 3D effect then you will have to decide between high density or puff print. While both produce embossed patterns, they are similar in outward appearance but feel different to the touch. They can yield fairly disappointing results if you mix them up.

By understanding these differences, it can help you select the right graphic design depending upon your field of business and branding strategy.

Feature | High Density Print | Puff Print |

Appearance | Sharp, crisp edges; flat top surface; a “Lego-like” block. | Rounded, soft, puffy edges; a “marshmallow-like” texture. |

Texture | Smooth, dense, rubbery feel. | Soft, spongy, light feel. |

Process | Ink is stacked in layers before the final cure. | A “puff” additive in the ink expands with heat during curing. |

Detail Level | Excellent for fine lines, text, and intricate logos. | Poor for fine details, as the puffing process blurs edges. |

Durability | Very High. Resists cracking and flattening over time. | Moderate. Can flatten or crack with repeated washing/stretching. |

Best For | Premium logos, architectural designs, minimalist text. | Vintage looks, cloud-like effects, fun and playful graphics. |

High Density Print Shirt Customization Options: For All Your Brand Needs

For apparel brands, we offer a wide range of custom high density print shirts designed to meet your exact branding requirements.

With our premium fabric selection, precise high density printing techniques, expert craftsmanship, garment accessories, personalized labels, and custom packaging options, you can create the exact shirt styles you envision.

Our goal is to help you deliver unique, high-impact designs that resonate with your customers and elevate your brand identity. As an experienced high density print shirt manufacturer, we provide comprehensive customization options to meet all your brand’s needs — whether you’re producing casual tees, fashion streetwear, or premium promotional apparel.

The Advantages and Limitations of High Density Printing

While high density printing has its advantages, it also comes with certain restrictions. This is how it works, so that you have a balanced impression of when it makes sense to apply this model.

Why You’ll Love It (The Pros)

- Unmatched Premium Feel: It instantly adds value and a luxurious quality to any garment.

- Exceptional Detail: Unlike puff, it keeps the sharpness of complex logos, fine lines, and text.

- Superior Durability: The dense, solid ink structure resists wear, washing, and cracking, so the design lasts.

- Versatile Look: The finish can be glossy for a sleek look or matte for a more subtle style.

What to Consider (The Cons)

- Higher Cost: The layering process, special materials, and longer setup times make it more expensive than standard printing.

- Less Breathability: The printed area isn’t breathable. This makes it better for logos than large chest designs.

- Fabric Limitations: The technique’s weight makes it unsuitable for very thin or stretchy fabrics.

Stiffness: The printed area will be less flexible than the surrounding fabric.

The Best Canvases: Choosing the Right Fabric for Your High Density Print Shirt

It’s not such a big deal with high density print shirts; the fabric is really critical but since ink is raised even though its heavier, it can still look good. So, choosing the right material prevents disaster and brings satisfactory results.

Why Fabric Choice is Critical

High density ink, because of its weight, cannot be printed on a flimsy or unstable fabric base. When it is too thin the design can make the material buckle where there is print. The fabric has to be strong enough to hold the print with warping

Recommended Fabrics

For making your design crisp and the hang of garment just right, use strong materials.

- Heavyweight Cotton: This is ideal. A stable, tight weave, especially in fabrics of 220 GSM (grams per square meter) or higher, provides the perfect surface for a crisp print.

- Cotton/Polyester Blends (CVC): Heavyweight blends are also excellent options. They offer the needed stability while adding durability.

- French Terry / Fleece: These materials, often used for hoodies and sweatshirts, have a dense structure that easily supports high density prints.

Fabrics to Avoid

This technique does not work for all fabrics. Lightweight jersey jerseys do not take the weight of the ink applied and, therefore, buckle. Do not print on spandex, which is too stretchy and has trouble holding a print without cracking when stretched. Avoid fabrics that are heavily ribbed and do not provide a smooth surface.

From Your Vision to a Tangible Product: A Partnership with ChengLin Clothing

Selecting a printing technique is only the beginning. There is no point in putting the answer out there. This is where a real manufacturing partner comes in handy.

27 Years of Printing Excellence

Now, with 27 years of hands-on garment manufacturing experience we offer our expertise at ChengLin Clothing. From ink formulation to curing, we have high density printing mastered and can help you make your design come out better than expected.

Your Dedicated Manufacturing Partner

We enable brands to execute their vision through the collaborative process of working with experts. We can walk you through design optimization, artwork preparation, and fabric construction to ensure high density shirt prints deliver on quality.

We understand the necessity of methods like high-density printing when it comes to developing brand identification. We are here to be the trusted banner production partner… for you.

Let’s Create Together

Are you looking to take your fashion brand to the next level with high-density prints that pop? Our developers will lead you through it all. Check out our services on our website.

For a direct consultation, please reach out to us.

- Direct Email: tesla@tuozhenclothing.com

- Phone/WhatsApp: +8613713252727

Conclusion: High Density Print Shirt

A high density print shirt is more than decorated apparel. It’s a premium product that creates a durable, sharp, 3D effect that customers can see and feel.

Success depends on expert execution, thoughtful design, and the right fabric choice. By understanding these elements, you can use this technique effectively.

In a competitive market, a high density print clearly distinguishes your brand, shows quality, and makes a lasting impression.

Real feedback from customers all over the world about ChengLin Manufacturer.

Communication & Production

How to Start Working with High Density Print Shirts Manufacturer?

3X

Your order is triple checked by our team prior to production and before shipment

Request a Free Quote & Consultation

Hit us up for a free quote. We’ll discuss your requirements — design, quantity, timing — and put a plan in place that works.

Submit Your Custom Design & Requirements

- Choosing High Density Print Shirts Material

- Selecting the right Carft for the design

- Payment for samples

- Sample production after determining the color, size, and accessories of the sample

Receive Sample Prototypes for Approval

- Are the fabrics satisfactory?

- Does the craftsmanship live up to the design?

- Are there any changes that need to be made to the colors, sizes, and accessories?

- Details of large orders

Bulk Production & Delivery Process

- Payment of deposit for large orders

- Large Order Production Progress Inquiry

- Final payment upon completion of production

- Choose the right shipping method, pay the shipping fee, ship the goods

FAQ

What is a high density print shirt and how does it differ from standard printing?

High density print shirts feature raised, 3D designs with a rubber-like texture created by layering special thick ink. Unlike standard printing, they provide both visual and tactile elements with sharper details and greater durability.

How much more expensive is high density printing compared to regular screen printing?

High density printing typically costs 30-50% more than standard screen printing due to specialized materials, longer production time, and the multi-layer application process required to achieve the raised effect.

What fabrics work best for high density print shirts?

Heavyweight cotton (220 GSM or higher), cotton/polyester blends, and French terry/fleece materials work best. Avoid thin jersey, stretchy fabrics with spandex, or heavily ribbed materials that can’t properly support the ink weight.

How durable are high density prints and will they crack over time?

Properly produced high density prints are extremely durable and resist cracking, flattening or fading through multiple washes when properly cured. They typically outlast standard prints and even puff prints.

What designs work best with high density printing techniques?

High density printing excels with logos, minimalist text, architectural designs, and graphics requiring sharp edges and fine details. It’s ideal for smaller, focused designs rather than large coverage areas due to breathability considerations.

High Density Print Shirts Manufacturer Offer

ChengLin High Density Print Shirts Manufacturer was created to provide helpful service, simple streamlined ordering & eco-friendly options. A company with transparent prices & ethics, a company that aims to create good things.

ChengLin High Density Print Shirts Manufacturer Difference

ChengLin was created, to provide helpful service, simple streamlined ordering & eco-friendly options. A company with transparent prices & ethics, a company who aims to create good things.

Innovative Ideas

ChengLin is proud to be a leading partner in the promotional products + fashion industry. With unique ideas + out of the box printing methods.

We Stand Behind Our Work

Our main goal is to provide peace of mind so you can relax and have confidence that your job will come out exactly as you had imagined.

Quality Over Quantity

ChengLin believes in quality over quantity and we want our customers to feel the same way.

Dedicated Reps

Each account receives a dedicated rep who can be reached face to face by phone or via e-mail.

Long Lasting Relationships

We value all of our clients and aim to solidify long lasting & mutually beneficial relationships.