A Manufacturer's Complete Guide to Foil Print Clothing: From Process to Lasting Shine

Introduction: The Enduring Allure of a Little Shine

There is something about a metallic sparkle, or shimmer that makes it so fashion sexy. This is did this to make a statement, lift up a design and say modern luxury.

As confirmed by recent fashion trends showcasing metallics, this appeal is not just timeless but it’s on the cutting edge.

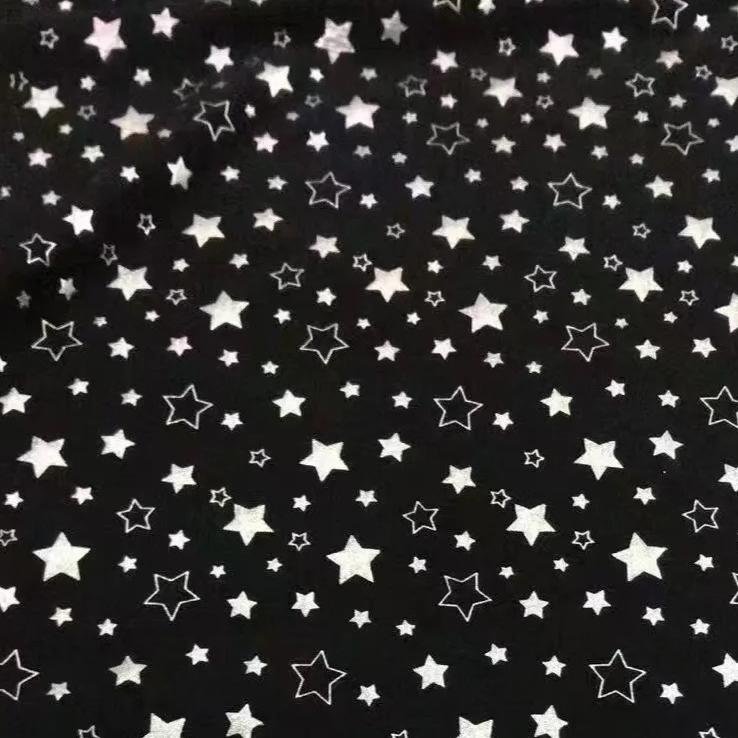

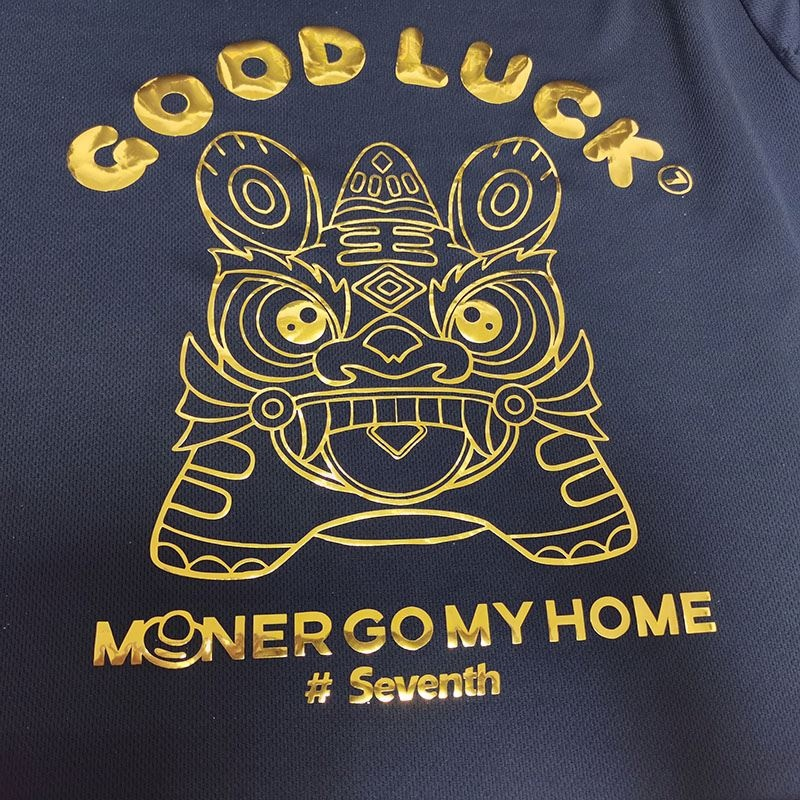

Foil print clothing is a high end decoration method that produces a bright, shiny metallic finish on garments. This is the kind of marketing used for mirror-like graphics and special shimmer in high-end fashion — both on catwalks and a fast-track to fancy display.

Getting it right and nailing a perfect, long-lasting foil print requires reliable information. And so success lies in proper process, correct weaving or even post handling.

This guide explains from A to Z part of the way. You will find out everything about its intricate making, you will compare them to see whether they suit your collection, you will know what are the most suitable fabrics for it, how to take care of a piece like that and learn how to team up with an expert manufacturer who will be able to deliver a good catwalk result.

The Art and Science: How Is Foil Printing Actually Done?

This helps designers and brand managers learn together about the production process to create good artwork for effective communication with your factory. So here is our professional approach to a foil print ‘behind the curtain’

And then the in-depth, methodical process — each step of which must be done exactly right to produce a luminous lasting finish.

Step 1: Artwork & Screen Preparation

It organizes the whole portrayal. The cleaner the artwork (vector always) the better. If the design has very fine details or thin, “whispy” textures that can be difficult for the adhesive to pick up evenly, it may shorten the lifespan of your print. As soon as art is finished, you make a mesh screen using the stencil within the design exactly like traditional silk screen printing.

Step 2: The Adhesive Layer

That is the essential base of the print. screen printing is a thick, clear adhesive applied with specialized equipment in the same shape as your design on the garment. To make the bond perfect, different fabrics ask for different type of glue which will be managed by a skilled manufacturer. The first round comes into play with silk screening, having to be carefully laid on a clean flat surface.

Step 3: Foil Application & Heat Curing

Once the adhesive is spread, a foil sheet is placed on top of the described design. This layer is an ultrathin metal skin situated on a transparent polyester carrier. Next the piece is set into a commercial heat press. Under such conditions the adhesive activates an combines with the foil. We usually run temperatures in the range of 300-325°F (150-163°C) and medium pressure settings for these, numbers which obviously need to be engineered perfectly for the particular fabric and foil combination we are working with.

Step 4: The “Cold Peel” Reveal

The apparel cannot be touch instantaneous it should be maintained after pressing. It needs to be refrigerated until it is completely cold. It is important to let it chill so that the bond can set. Once cooled, strip the foil carrier sheet away in a continuous motion. This is also known as the cold pill stage. The metallic foil is always bonded on the adhesive which stays on to the fabric leaving a beautiful sharp and vibrant copy of the original design.

Pro Tip: ChengLin is ideal for brands looking for reliability, quality, and creativity in foil print clothing manufacturing. Here’s a comprehensive look at why ChengLin should be your first choice for custom foil print apparel production.

Is Foil Printing Right for Your Collection? A Balanced Look at Pros and Cons

The lesson here is that every decoration technique has its place: it’s all about choosing the right one for your product, brand and target customer. While foil printing provides an amazing impact, remember to measure the benefits against its constrictions.

A more balanced perspective and framework to know if this technique is suitable for your next collection.

Advantages of Foil Printing | Considerations & Disadvantages |

High-Impact Visual Appeal: Creates a brilliant, mirror-like finish that is impossible to achieve with standard inks. It looks expensive and immediately grabs attention. | Durability Nuances: The print is a topical layer. While durable when properly applied and cared for, it is more susceptible to abrasion and high heat than standard inks. |

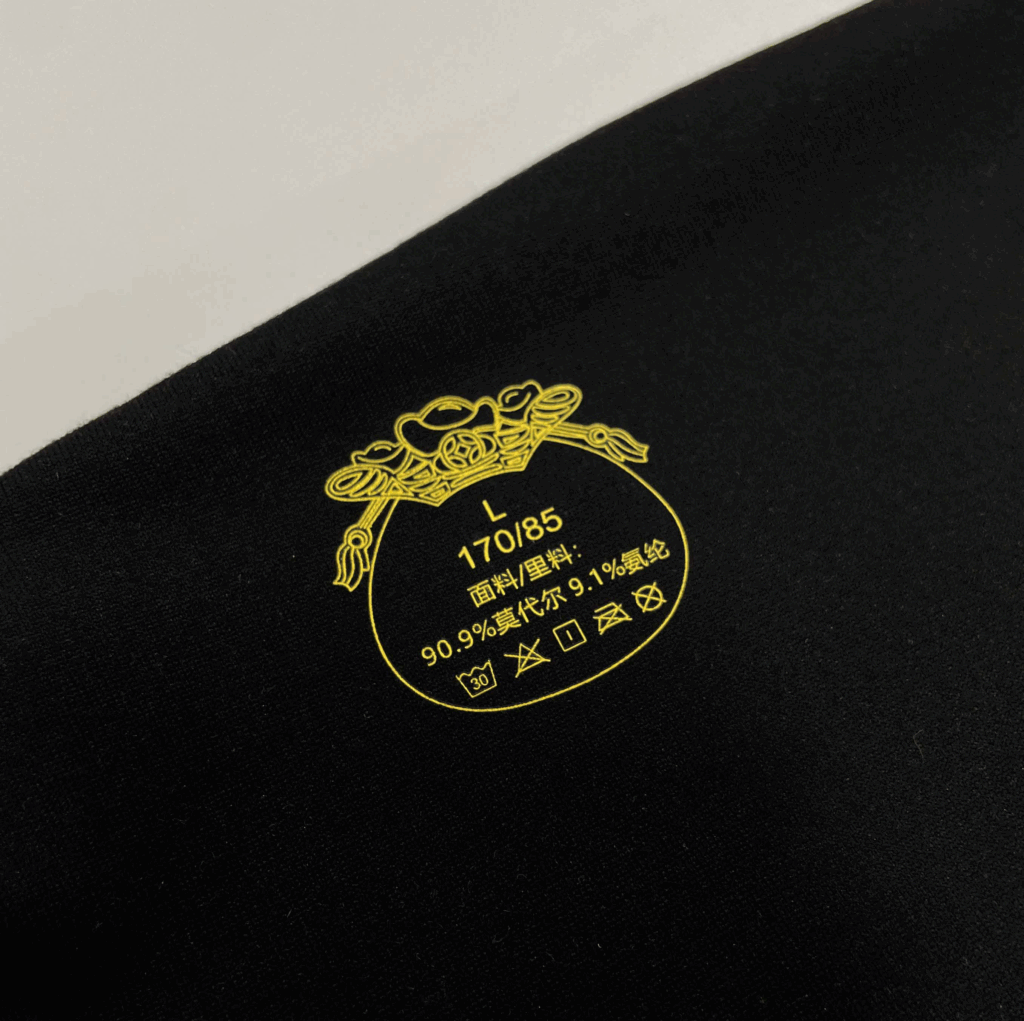

Texture & Finish Versatility: Available in a wide range of colors beyond gold and silver, including holographic, patterned, and even matte metallic finishes. | Care Instructions Required: Garments require specific washing instructions (cold wash, hang dry). This must be communicated clearly to the end consumer on the care label. |

Perceived High Value: The luxurious look of foil can elevate a simple garment like a t-shirt or hoodie, allowing for a higher retail price point. | Design Limitations: Very intricate, fine-detail designs or designs with sharp, thin lines can be challenging to execute perfectly and may have longevity issues. |

Excellent Opacity: Foil is completely opaque, making it a fantastic choice for bold, solid graphics on both light and dark-colored fabrics. | Not Breathable: The foiled area is non-breathable as it is a solid layer of adhesive and foil. This should be considered for large, solid prints on performance or summer-weight garments. |

Foil Print Clothing Customization Options: For All Your Brand Needs

For apparel brands, we offer a wide range of custom foil print clothing styles and personalized embellishment options tailored to your brand’s exact specifications.

With our premium selection of base fabrics, expert foil printing craftsmanship, garment trims, personalized neck labels, and custom packaging, you can develop standout pieces that reflect your unique brand identity and catch the eye with a luxurious metallic shine.

Our goal is to help you deliver apparel that resonates with your customers and elevates your product line. Understanding the importance of customization, we provide full-service solutions for foil print t-shirts, hoodies, sweatshirts, and fashion tops, ensuring every detail meets your creative and quality standards.

Choosing the Right Canvas: The Best (and Worst) Fabrics for Foil Printing

The type of fabric you use is just as crucial as the printing format. Surface texture, fiber content and heat resistance of the material all effect the print quality as well as how long it will last.

We have been manufacturing for 27 years and we can give you firsthand experience of how using the correct fabric can make or brake a foil print. By making the right decision during design, you can save your business from production headaches and give your customers a quality product that will last.

Best Choices (Smooth & Stable)

- 100% Combed Cotton: This is an ideal canvas. Its smooth, tight-knit, and stable surface provides the perfect base for the adhesive to bond flatly and securely. The strength of the technical compatibility between foil adhesive and cotton fibers makes it a reliable and highly recommended option.

- Cotton/Polyester Blends (e.g., 50/50, CVC): These blends are also excellent choices. They maintain a smooth surface, resist shrinking, and handle the heat press process extremely well, resulting in a clean and durable print.

Use With Caution (Requires Testing)

- Ribbed Knits (e.g., 2×1 Rib): The challenge here is the uneven surface. The foil adheres perfectly to the “peaks” of the ribs, but may not fully bond in the “valleys.” This can create a naturally distressed or striped look, which can be a great design feature if intended, but a production flaw if not. We always recommend pre-production sampling for these fabrics.

Generally Avoid (High Risk of Failure)

- Heat-Sensitive Synthetics (e.g., certain 100% polyesters, nylon, spandex): The high temperatures required for foil printing (300°F+) can permanently scorch, melt, or leave shining press marks on these delicate fabrics. While some performance polyesters are engineered for heat, they must be tested extensively.

- Loosely Woven or Heavily Textured Fabrics (e.g., Terry Cloth, some Fleece): A smooth, solid foundation is non-negotiable for a clean foil print. The uneven surfaces and loose fibers of these materials prevent the adhesive from creating a consistent, solid bond, leading to a flaky, incomplete, and non-durable result.

Your Partner in Production: Why Experience Matters for Foil Printing

Foil Print Clothing Run The Right Equipment Alone is Not Enough To Successfully Produce High-Quality Foil Print Clothing Artwork, Adhesives, foils and fabrics all behave differently depending on the heat and pressure point.

To get that gleaming, durable surface your brand deserves, you need a manufacturer who knows every aspect of the process.

ChengLin Clothing has had 27 years to develop this method through clothing copious amounts of different projects and fabric types. We are not a factory but a partner for the production of your vision, providing perfect quality and attention to detail.

Our skill extends to everything from consultation on adjusting artwork and a scrupulous fabric quality selection process, to an ultra-precise grading of the printing system. We make sure that your end product lives up to the beauty of designs but also displays the durability to carry forward your brand for years.

Ready to add some shine to your next collection? We’re here to help guide you through the process. Reach out to our team to discuss your project.

● Direct Email: tesla@tuozhenclothing.com

● Phone Number: +8613713252727

● WhatsApp: +8613713252727

● Explore More of Our Services: ChengLin Clothing

Conclusion: Making a Lasting Impression

Foil Printing continues to be one of the greatest weapons in an apparel designer’s arsenal when it comes to creating visually appealing, noteworthy garments that will help make a lasting impact in a clothing store filled with products.

And as we’ve examined, real success comes only if all three of these areas of knowledge are mastered: understanding the technical to properly manipulate it, choosing the right fabric for the job and communicating how to care for it clearly to users.

With this expert knowledge and the correct manufacturing partner in your corner helping you, your brand can be confident that it will have disposed to a foil print that will not only look great on day one but for all its life wash after wash.

Real feedback from customers all over the world about ChengLin Manufacturer.

Communication & Production

How to Start Working with Foil Print Clothing Manufacturer?

3X

Your order is triple checked by our team prior to production and before shipment

Request a Free Quote & Consultation

Hit us up for a free quote. We’ll discuss your requirements — design, quantity, timing — and put a plan in place that works.

Submit Your Custom Design & Requirements

- Choosing Foil Print Clothing Material

- Selecting the right Carft for the design

- Payment for samples

- Sample production after determining the color, size, and accessories of the sample

Receive Sample Prototypes for Approval

- Are the fabrics satisfactory?

- Does the craftsmanship live up to the design?

- Are there any changes that need to be made to the colors, sizes, and accessories?

- Details of large orders

Bulk Production & Delivery Process

- Payment of deposit for large orders

- Large Order Production Progress Inquiry

- Final payment upon completion of production

- Choose the right shipping method, pay the shipping fee, ship the goods

FAQ

What is foil print clothing and how is it different from regular printed garments?

Foil print clothing features a metallic, reflective finish created by bonding specialized foil to fabric using heat-activated adhesive, offering a luxury appearance that regular printing techniques cannot achieve.

Which fabrics work best for foil printing in 2025?

100% combed cotton and cotton/polyester blends work excellently for foil printing, providing smooth surfaces for optimal adhesion, while heat-sensitive synthetics and heavily textured fabrics should be avoided.

How long does foil print clothing last with proper care?

With proper care (cold washing, hang drying, avoiding abrasion), high-quality foil print clothing can maintain its shine and appearance for years, though it requires more careful handling than standard printed garments.

What are the main advantages of using foil print on clothing collections?

Foil print clothing offers high-impact visual appeal, texture versatility, perceived luxury value, and excellent opacity on both light and dark fabrics, allowing brands to command premium pricing.

Can foil printing be applied to performance athletic wear?

Foil printing can be applied to certain performance fabrics, but requires careful testing as the foiled areas aren’t breathable and some technical fabrics may be heat-sensitive, potentially affecting the garment’s performance properties.

Foil Print Clothing Manufacturer Offer

ChengLin Foil Print Clothing Manufacturer was created to provide helpful service, simple streamlined ordering & eco-friendly options. A company with transparent prices & ethics, a company that aims to create good things.

ChengLin Foil Print Clothing Manufacturer Difference

ChengLin was created, to provide helpful service, simple streamlined ordering & eco-friendly options. A company with transparent prices & ethics, a company who aims to create good things.

Innovative Ideas

ChengLin is proud to be a leading partner in the promotional products + fashion industry. With unique ideas + out of the box printing methods.

We Stand Behind Our Work

Our main goal is to provide peace of mind so you can relax and have confidence that your job will come out exactly as you had imagined.

Quality Over Quantity

ChengLin believes in quality over quantity and we want our customers to feel the same way.

Dedicated Reps

Each account receives a dedicated rep who can be reached face to face by phone or via e-mail.

Long Lasting Relationships

We value all of our clients and aim to solidify long lasting & mutually beneficial relationships.