Discharge T Shirt Printing: The Expert's Guide to Ultra-Soft, Premium Prints

Fingers crossed that this means the end of cheap, plastic-y feeling designs that crack and peel over time. The texture of a print matters as much to many apparel brands that are committed to quality, if not even more so than the design.

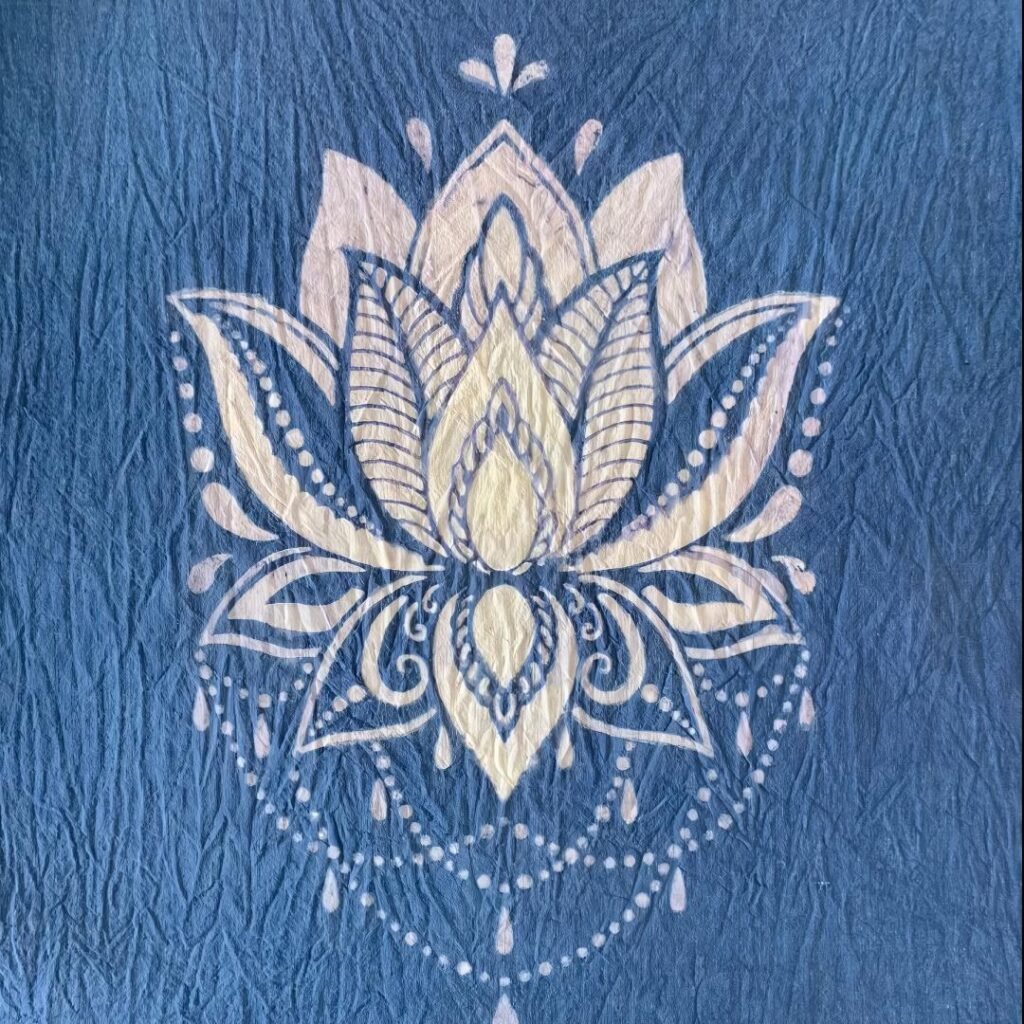

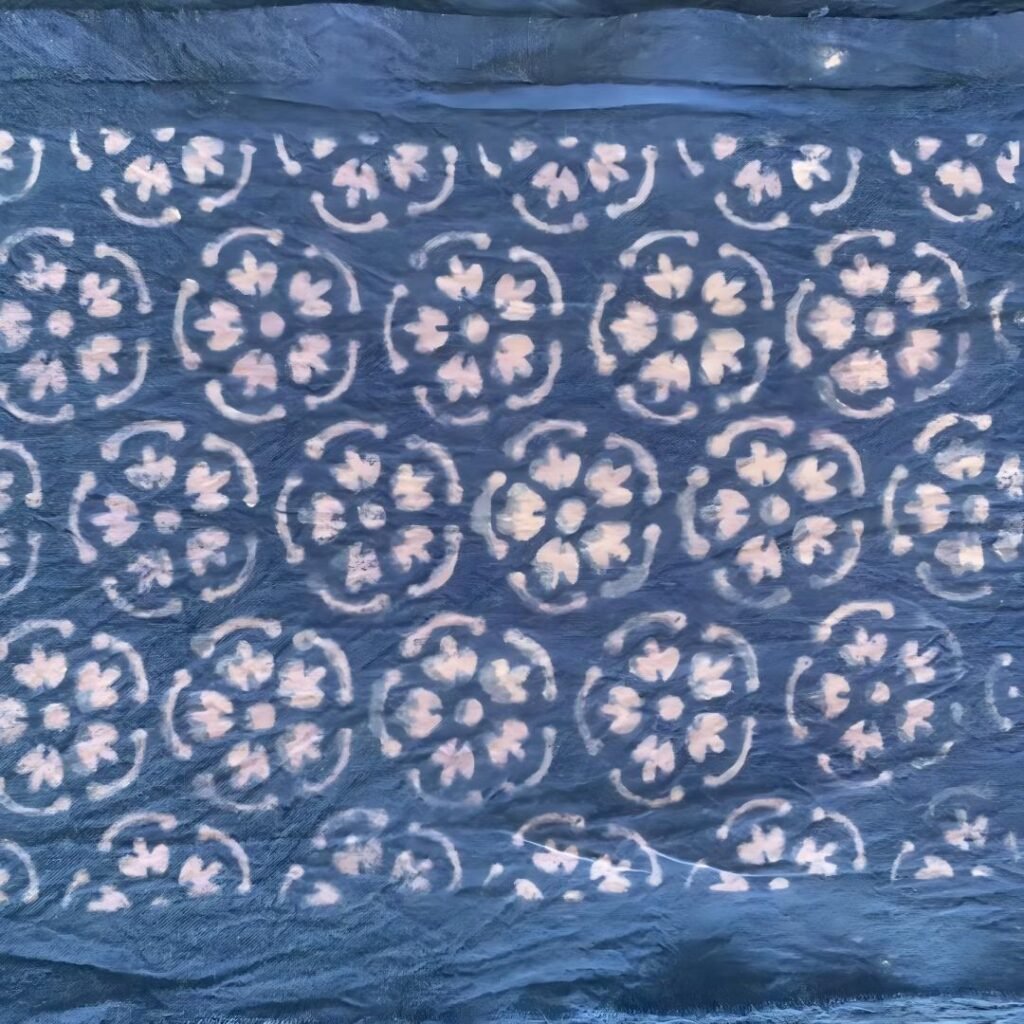

The discharge t-shirt printing is the answer. This is highly evolved screen printing process because it works by using a unique water based ink that extracts the dye straight from the fibers in to –marginTop:0px!important. Discharge printing, on the other hand, removes the existing color and replaces it with the pigment you selected instead of laying an additional layer of ink over your garment.

The result is a print that physically feels like there’s nothing there. This creates a higher level of breathability, more strength on seams and an aged look that only comes with age on any garment. That’s what makes it a favourite for brands which do not want to be seen as the brand that caved in to comfort or quality.

How It Works: The Science Behind the Softness

The degree to which this happens is explained by the discharge process, and this understanding is what explains why Ba+1 yields such a high-quality result. When heat is applied it causes a chemical reaction and not just transferring the ink. For decades, we have been riding on the experience and work we put in at ChengLin Clothing to perfect this method in achieving consistent high-quality results.

This technique can be broken down into four vital stages.

- Ink Formulation: We begin by mixing a special water-based ink with a discharge activator. This activator is a chemical agent, similar in function to a color-safe bleach, that is designed to neutralize the specific dyes used in natural fabrics.

- Screen Printing Application: The ink mixture is then applied to the t-shirt using the same method as traditional screen printing. A squeegee pushes the ink through a mesh screen stenciled with your design, transferring the formula onto the garment.

- The Heat Activation (Curing): This is the critical step where the magic happens. As the printed t-shirt passes through a large conveyor dryer, the heat activates the discharge agent. This chemical reaction systematically strips the original dye from the cotton fibers in the design area. Precision is essential, as getting the curing process right is what ensures a bright and complete print.

- Dye Replacement: Simultaneously, the pigment within the water-based ink sets into the now-colorless fibers, re-dyeing them with your design’s color. Because the design is now part of the fabric rather than a layer on top of it, the print is completely breathable and has a “zero hand” feel.

Pro Tip: ChengLin is ideal for brands seeking reliability, premium quality, and creative excellence in discharge t-shirt printing. Here’s why ChengLin should be your top choice for custom discharge print t-shirts that combine softness, durability, and a true retail-ready look.

The Manufacturer's View: Discharge vs. Plastisol Screen Printing

So as a brand owner, the red pill / blue pill shit gets even more real when you start deciding between discharge and plastisol ink. Having been in the manufacturing business for 27 years, we can say assuredly that there is no universally “best” method — it all depends on your fabric, design, and brand image.

Plastisol — A type of ink that when heat-cured, remains an oil-based substance which acts as a solid deposit above the fabric and provides a vibrant print. Discharge is actually a water based ink system that replaces the fabric dye with a soft and breathable print, leaving it matte.

We have listed the top differences (after tens of thousands of production runs) to help that you be able to decide.

Feature | Discharge Printing | Plastisol Ink Printing |

Feel & Texture | Ultra-soft, no feel (“zero hand”), breathable | Thicker, sits on top of fabric, can feel heavy or stiff |

Best on Fabrics | Dark, 100% natural fibers (e.g., cotton) | Versatile; works on cotton, blends, and synthetics |

Vibrancy & Look | Matte, slightly vintage finish (colors can vary) | Bright, opaque, vibrant colors with a glossy finish |

Color Matching | Good, but exact PMS matching can be a challenge | Excellent for precise Pantone (PMS) color matching |

Durability | Lasts as long as the garment, will not crack or peel | Very durable, but can crack or peel over time with wear |

Ideal For | Premium fashion, vintage aesthetics, large prints | Corporate logos, sportswear, bold graphic designs |

So, in conclusion of the above choose discharge for an ultimate maximum comfort and very large print, give your prints a look that is more vintage or premium fashion. Plastisol is a good choice for projects where the colors need to be perfect (matching Pantone colors, printing on synthetic blends) as well as any project that requires a strong, vibrant, glossy graphic.

Although we are known for our technical prowess in the realm of discharge — specifically water-based, no-needle-through-water models — we provide a complete range of printing options. This includes providing services for traditional screen printing projects where the use of plastisolink is inevitable.

Discharge T Shirt Printing Customization Options: For All Your Brand Needs

For apparel brands, we offer a wide range of custom discharge print t-shirt styles and highly personalized branding options tailored to your vision.

With our deep expertise in discharge t shirt printing, fabric selection, garment construction, label design, and packaging solutions, you can create ultra-soft, vintage-style t-shirts that truly reflect your brand.

Our goal is to help you deliver garments that resonate with your customers and elevate your brand identity. As a specialized discharge t-shirt manufacturer, we provide full customization services — whether you’re designing fashion-forward collections, streetwear drops, or premium retail lines.

The Golden Rules: Choosing the Right Fabrics and Colors for Discharge

Discharge printing success is determined well before the ink hits your screen. If you select the appropriate garment entirely depends on this. The chemistry of the process dictates what fabrics will work and what dye colors can be achieved or not, and what will result in an expensive error.

Why 100% Cotton is King

Our discharge agent is designed to have a reaction with only the reactive dyes traditionally used when dyeing natural fibers, like cotton, bamboo or hemp. This will not be useful on synthetic fibers (ex: polyester, nylon these are dyed using different dyeing process).

All of the years we have been discharge screen printing with perfect waterbase results led us to believe that 100% combed or ringspun cotton has given us the most consistent, vibrant and reliable discharge prints. These high-end cotton that has a smoother finish that is the perfect medium for even better printing & decent final hand.

The “Gamble” of Blends (50/50, Tri-Blends)

Fabric: While cotton/poly blends are a reality, it is essential to remember that they will yield a drastically different result and should be considered an intentional design decision rather than the norm.

On a 50/50 blend, the chemical agent in discharge ink will remove the dye from cotton fibers but not from the polyester ones. As a result the print itself has a “heathered” or muted effect.

The 50/50 blend can be the perfect choice for your retro concert tee with its muted, heathered print that enhances the authentic vintage vibe; However, if you are a brand that demands a clean, crisp white print then that would be an inappropriate selection. Of course, we always check with the clients to see if this effect jives with their creative vision.

Not All Colors Are Created Equal

Different dyes for different fabrics Some of the dyes are made from chemicals which are very resistant to the discharge agent. Print discharge on these colors will be weak, wishy-washy and full of desaturation and is the most difficult color for a print-discharge mix to come out right.

Our production data shows the dye colors according with manufacturer’s guide:

- Excellent Results: These colors discharge reliably for a bright and clean print.

- Black, Navy, Brown, Dark Grey, Burgundy, Olive.

- Good but Variable Results: These colors will discharge, but the final shade can vary slightly from batch to batch, creating a unique look.

- Red, Maroon, Forest Green, Dark Chocolate.

- Difficult/Do Not Discharge: The chemical composition of these dyes makes them highly resistant. We strongly advise against using them for discharge projects.

- Royal Blue, Kelly Green, Purple, Teal.

Partner with the Experts: Achieving Flawless Discharge Prints with ChengLin Clothing

For the best discharge printing results, it is extremely important to learn as much as you can about fabrics, dyes and designs. Top notch re-labeling and custom hang tags are provided, 27 yearsof clothing manufacturing experience turns an okay t-shirt to a great one!

We’ve encountered everything: challenging fabrics, unexpected dye treatments and newly created designs. This is to advise our clients of common pitfalls; how deep goes the rabbit hole. But we printed and even offered advice.

At ChengLin Clothing, we execute to perfection. Our colour removal process only uses the best modern, formaldehyde-free discharge agents with meticulous process control. We offer pre-production samples of your selected garments so that you can get a sense for how your design will turn out using this premium technique before committing to any production run.

We are not just an OEM supplier, we are your production partner with a mission to deliver the highest quality products and life your brand’s vision.

Willing to Print a Soft Touch Feel on your T-shirt? Let’s talk about your project.

- Direct Email: tesla@tuozhenclothing.com

- Phone/WhatsApp: +8613713252727

Conclusion: The Final Word on Discharge T-Shirt Printing

This means that those who choose to discharge print their t-shirts are not only employing a technique, but also making a testament of the quality they value. It positions you r customer to think, these people have thought of EVERYTHING including what the print on it feels like. Fabric choral dyeing generates a special softness and sophistication while working with a process that is almost unrivalled, if ever.

Here are the key takeaways:

- Discharge printing removes a garment’s dye to re-color the fibers, creating the softest possible print.

- It is the ideal choice for premium, vintage-style designs on dark, 100% cotton garments.

- Success depends heavily on choosing a garment with the right kind of dye (reactive dyes).

- Working with an experienced manufacturing partner is the key to navigating its complexities and avoiding costly mistakes.

When you want to take your clothing line to an entirely new level with a print that actually becomes part of the garment, we are ready and able.

Real feedback from customers all over the world about ChengLin Activewear Manufacturer.

Communication & Production

How to Start Working with Discharge T-Shirt Printing Manufacturer?

3X

Your order is triple checked by our team prior to production and before shipment

Request a Free Quote & Consultation

Hit us up for a free quote. We’ll discuss your requirements — design, quantity, timing — and put a plan in place that works.

Submit Your Custom Design & Requirements

- Choosing Discharge T-Shirt Printing Material

- Selecting the right Carft for the design

- Payment for samples

- Sample production after determining the color, size, and accessories of the sample

Receive Sample Prototypes for Approval

- Are the fabrics satisfactory?

- Does the craftsmanship live up to the design?

- Are there any changes that need to be made to the colors, sizes, and accessories?

- Details of large orders

Bulk Production & Delivery Process

- Payment of deposit for large orders

- Large Order Production Progress Inquiry

- Final payment upon completion of production

- Choose the right shipping method, pay the shipping fee, ship the goods

FAQ

What makes discharge t shirt printing different from regular screen printing?

Discharge printing removes the original dye from fabric and replaces it with new pigment, creating prints that feel like part of the shirt rather than sitting on top like traditional methods.

What fabrics work best for discharge t shirt printing in 2025?

100% cotton fabrics yield the best results for discharge printing, while cotton/polyester blends create a heathered effect and some synthetics aren’t suitable for this technique.

How long do discharge t shirt prints last compared to plastisol prints?

Discharge printed designs typically last as long as the garment itself without cracking or peeling, while plastisol prints can deteriorate over time with repeated washing and wear.

Can all t-shirt colors be used for discharge printing?

No, certain dye colors like Royal Blue, Kelly Green, and Purple resist the discharge process, while colors like Black, Navy, and Burgundy produce excellent results.

Why do premium apparel brands prefer discharge t shirt printing in 2025?

Premium brands choose discharge printing for its ultra-soft “zero hand” feel, superior breathability, vintage aesthetic, and exceptional durability that elevates the quality of their garments.

Discharge T-Shirt Printing Manufacturer Offer

ChengLin Discharge T-Shirt Printing Manufacturer was created to provide helpful service, simple streamlined ordering & eco-friendly options. A company with transparent prices & ethics, a company that aims to create good things.

ChengLin Discharge T-Shirt Printing Manufacturer Difference

ChengLin was created, to provide helpful service, simple streamlined ordering & eco-friendly options. A company with transparent prices & ethics, a company who aims to create good things.

Innovative Ideas

ChengLin is proud to be a leading partner in the promotional products + fashion industry. With unique ideas + out of the box printing methods.

We Stand Behind Our Work

Our main goal is to provide peace of mind so you can relax and have confidence that your job will come out exactly as you had imagined.

Quality Over Quantity

ChengLin believes in quality over quantity and we want our customers to feel the same way.

Dedicated Reps

Each account receives a dedicated rep who can be reached face to face by phone or via e-mail.

Long Lasting Relationships

We value all of our clients and aim to solidify long lasting & mutually beneficial relationships.