The Ultimate Guide to Clothing Screen Print: Techniques for Premium Apparel

Apparel screen printing is the heart and soul of the custom apparel business. It’s prized for vibrant colors, enduring quality and numerous uses. The biggest brands trust this process to produce clothes that are built to last. But screen printing is not all the same. The techniques you choose will influence how your clothing feels, looks and appears to others.

This isn’t just your average screen printing overview. So we’ve utilized our 27 years of experience in making clothes through Tuozhen Clothing to provide you expert advice. This guide is that, and then some, to help you find the right option that’s best for your brand.

- Understanding the Fundamentals: How does a design actually get onto a shirt?

- A Deep Dive into Techniques: A detailed look at 8 essential print methods, from industry standards to specialty finishes.

- A Practical Decision Framework: How to choose the perfect technique based on your fabric, design, and brand goals.

- Partnering for Success: Why the right manufacturing partner is crucial for flawless execution.

Understanding the Core of Clothing Screen Printing

Before you focus on one method, you should gain an understanding of the process as a whole. Screen printing is a popular and durable method for custom apparel. It’s the force and push of ink through a stencil on fabric that makes for a strong bond. This bond is a lot stronger than a standard surface print. Learning this skill is what distinguishes printmakers from t-shirt sellers.

How a Design Goes from Screen to T-shirt: The Basic Steps

We can break down this time-tested method into five main stages. Each step is important for the quality of your final product.

- Design & Film: Your artwork is printed onto a clear film. The darkness and clarity of this film are crucial. Any flaw here will show up in the final screen.

- Screen Preparation: A mesh screen gets coated with light-sensitive emulsion. How evenly this coating is applied affects how much ink passes through. This directly impacts the print’s clarity and thickness.

- Exposure: The film is placed on the coated screen and exposed to strong UV light. The light hardens the emulsion around the design. Black areas of the film block light, leaving those parts of the emulsion soft. The screen is then washed, and the soft emulsion rinses away. This creates a perfect stencil of your design.

- Ink Application: The screen is placed on the garment. Ink is poured onto the screen. A squeegee pulls the ink across the stencil, pushing it through the open mesh areas and onto the fabric. The angle, pressure, and speed of the squeegee are all factors that a skilled printer controls for a perfect print.

Curing: The garment passes through a large dryer. The ink must reach a specific temperature for a set time to cure permanently. We’ve seen many brands suffer from poor curing. If under-cured, the ink will crack and wash out. This step is essential for durability.

Pro Tip: ChengLin is ideal for brands seeking reliability, quality, and creative precision in clothing screen printing. Here’s a comprehensive look at why ChengLin should be your first choice for custom screen printing on all types of garments and fashion apparel.

A Deep Dive: 10 Essential Clothing Screen Print Techniques for Apparel

Picking the right method matters a lot. The ink type, how it’s put on, and the final look can change how a garment looks, feels, and works. Here, we explain nine key methods we often use for top clothing brands.

Water-based ink has water as its main part. The ink soaks into the fabric fibers instead of sitting on top, giving a very soft feel.

- Pros: Very soft touch, breathable, better for the earth than plastisol, great for a vintage or high-end look.

- Cons: Less solid on dark clothes (may need an underbase), color matching can be harder, costs more.

- Best For: Light-colored 100% cotton items, linen, and blends where air flow and a soft, premium feel matter most.

Rubber Print

Rubber print uses a stretchy, rubber-like ink. It makes a thick, raised layer of ink that stretches well and covers fully.

- Pros: Shows up well on dark fabrics, stretches and bounces back great, lasts long, has a slightly raised feel.

- Cons: Can feel heavy on thin clothes, less breathable than water-based ink.

- Best For: Sports clothes, stretch fabrics, and designs on dark-colored items that need bright, solid color fills.

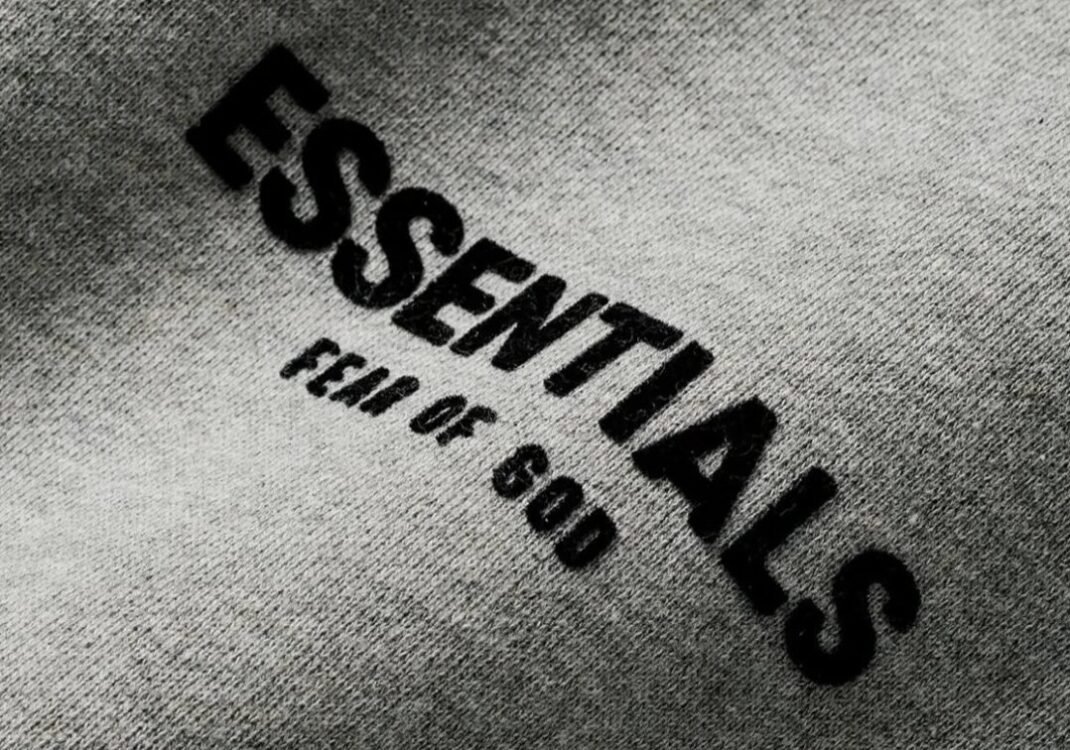

Plastisol is the standard in the industry. It’s a PVC-based ink that stays on top of the fabric rather than soaking in. It forms a strong, lasting, and solid layer of plastic ink.

- Pros: Great color brightness and coverage, very durable, cost-effective for big orders, easy to match colors (PANTONE).

- Cons: Can feel heavier and plastic-like, less breathable, not as green.

- Best For: Many types of clothes, including t-shirts, hoodies, and promo items. Works well on both light and dark fabrics, mainly 100% cotton.

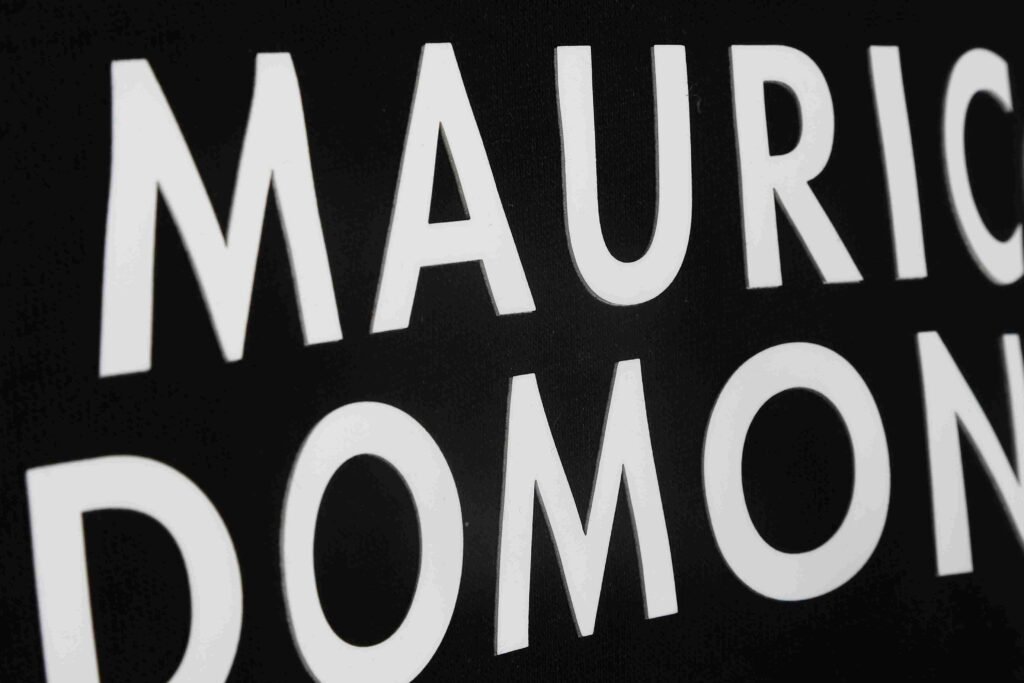

High Density printing uses a special kind of plastisol ink and many screen layers to make a sharp-edged, three-dimensional, “embossed” effect.

- Pros: Creates a striking 3D or “brick-like” texture, high-end look, very lasting.

- Cons: Can be stiff and not flexible, costs more due to special screens and many ink layers, not good for large designs.

- Best For: Logos, small text, and graphic elements on a premium item where a touch-based, high-impact effect is wanted. Common on hats, hoodies, and jackets.

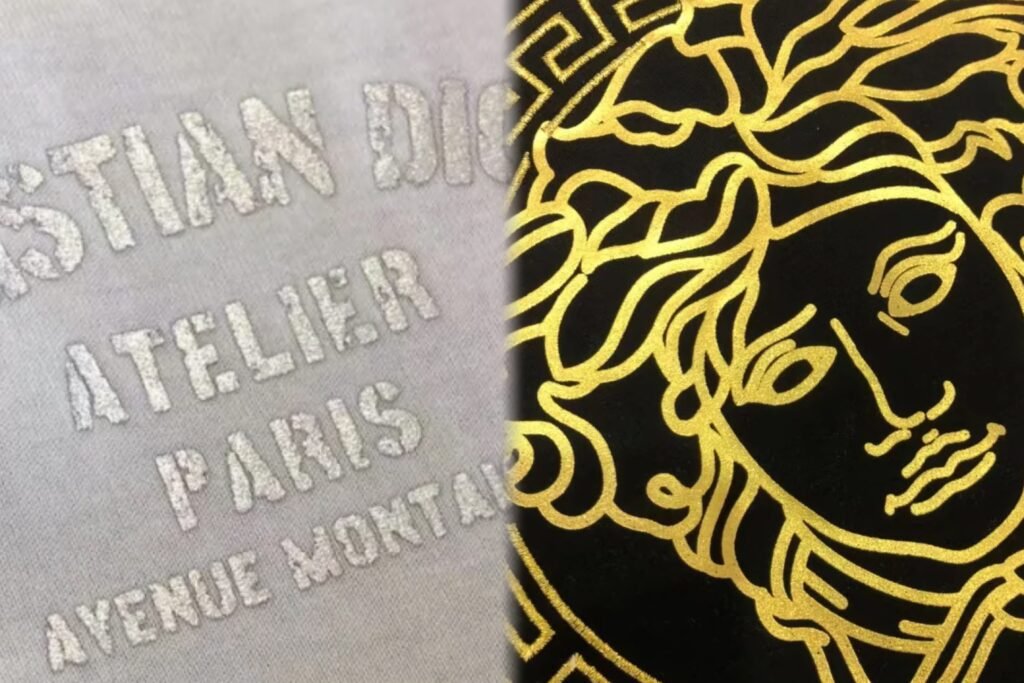

This is a two-step process. First, a special glue is screen-printed onto the garment in the design’s shape. Then, a thin sheet of metallic foil is heat-pressed onto the glue, sticking only to the printed areas.

- Pros: Bright, shiny metallic finish, makes a luxury or high-fashion look.

- Cons: Less durable than standard inks (needs gentle washing), doesn’t stretch, can cost more.

- Best For: Statement pieces, fashion clothes, and special edition goods. Best on stable fabrics like cotton and polyester blends.

Discharge printing uses a water-based ink with a chemical that removes the dye from the fabric itself. The ink then re-dyes the fabric in the design area.

- Pros: Zero-feel “hand”—the print is literally part of the fabric, very soft and breathable, perfect for a vintage look.

- Cons: Only works on 100% cotton or high-cotton blends with reactive dyes, color matching is less exact, may have a slight smell before the first wash.

- Best For: Premium t-shirts and fashion clothes on dark, 100% cotton items to get an ultra-soft, breathable print.

Flock printing puts a glue on the garment and then applies tiny fibers (flock) over it. A static charge makes the fibers stand up, creating a soft, velvety feel after curing.

- Pros: Unique, soft, velvet-like or suede feel, creates a premium and retro look.

- Cons: Limited fine detail, needs careful washing, can cost more than standard prints.

- Best For: College wear, retro designs, and adding texture to logos and graphics on hoodies, crewnecks, and jackets.

Silicone ink is a premium choice known for its extreme stretch and durability. It can be put on in thick layers to create a high-density, sharp 3D effect with a smooth, rubbery feel.

- Pros: Better stretch and bounce back, very durable and wash-resistant, high-end matte or glossy finish, sharp detail.

- Cons: Higher cost, slower production process.

- Best For: Performance and athletic wear (like Nike or Adidas logos), stretch fabrics, and any item needing maximum durability and flexibility.

Puff ink has a heat-activated foaming agent. When the ink is cured, it expands and rises, creating a soft, three-dimensional “puffy” texture.

- Pros: Makes a fun, raised, and touch-based 3D effect, adds visual interest to simple designs.

- Cons: Can lose its “puff” over time with many washes, not good for highly detailed designs.

- Best For: Bold text, cartoon-like graphics, and novelty t-shirts. Works well on cotton and poly-cotton blends.

Reflective Printing

Reflective printing uses light-reactive materials that reflect light when illuminated, especially in low-light conditions. It adds both functionality and style, making garments more visible at night and giving a futuristic or streetwear edge.

Pros:

✅ Enhanced visibility and safety in low light

✅ Unique metallic or mirror-like visual effect

✅ Adds functional and design value

✅ Works on a variety of fabricsCons:

❗ Slightly stiffer feel compared to regular inks

❗ May require special care when washingBest For:

• Streetwear and fashion-forward designs

• Sportswear, cycling, running gear

• Safety clothing or night-use apparel

ChengLin Clothing – Expert Screen Printing for Custom Clothing and Fashion Brands

For apparel brands, we provide a full range of clothing screen printing solutions, combined with custom garment styles tailored to your unique branding needs.

From high-quality graphic tees to bold logo hoodies, our expert screen printing techniques ensure crisp, durable prints that bring your designs to life.

With a wide selection of fabrics, advanced screen printing craftsmanship, garment trims, personalized labels, and custom packaging options, we help turn your creative vision into reality.

Our mission is to help you create standout apparel that resonates with your customers and reinforces your brand identity. As a trusted clothing manufacturer, we understand how impactful professional screen printing can be in making your products visually compelling. Whether you’re launching casualwear, fashion collections, promotional merchandise, or exclusive drops, we offer end-to-end customization to meet all your screen printing needs.

The Right Choice for Your Brand: A Comparative Framework

With our 27 years of clothing experience, we’ve learned that the best print technique is a strategic choice, not just a technical one. Your decision impacts your brand’s perception, the garment’s comfort, and your production budget. Ask yourself: are you aiming for luxury, performance, comfort, or a vintage aesthetic?

The choice of technique shows your brand’s commitment to quality and lifts the simple act of printing into a powerful design element, much like artists have used the artistic potential of screen printing for decades.

This table provides a manufacturer’s comparison to help you align your vision with the right process.

Technique Name | Feel (Hand) | Durability | Vibrancy/Opacity | Best Fabric Match | Common Use-Case |

Water-Based | Very Soft | Good | Medium (Vibrant on light fabric) | Light-colored 100% Cotton | Premium fashion, vintage tees |

Rubber Print | Flexible, Thick | Very Good | High | Cotton, Polyester, Stretch Blends | Sportswear, dark garments |

Plastisol | Slightly Heavy | Excellent | High | 100% Cotton, Poly-Blends | General apparel, promotional tees |

High Density (HD) | Hard, Raised | Excellent | High | Cotton, Polyester, Heavyweights | Logos, high-end branding, hats |

Gold Foil | Smooth, Stiff | Moderate | N/A (Metallic sheen) | Cotton, Poly-Blends (non-stretch) | Fashion items, statement pieces |

Discharge | No Feel | Excellent | Vintage/Muted | 100% Cotton (reactive dyes) | Premium tees, distressed looks |

Flock | Soft, Velvety | Good | N/A (Textured fiber) | Cotton, Hoodies, Crewnecks | Retro designs, collegiate wear |

Silicone 3D | Smooth, Rubbery | Superior | High | Performance fabrics, Lycra, Spandex | High-end athletic wear |

Puff | Soft, Puffy | Good | Medium | Cotton, Poly-Blends | Novelty shirts, bold text |

Your Partner in Excellence: Why Experience Matters in Apparel Printing

Choosing a maker is about more than just tools. It’s about deep knowledge of how ink chemistry, fabric type, and curing technology work together. With 27 years of clothing experience, we’ve mastered this mix.

A skilled maker foresees problems—like dye migration on polyester or fibrillation on cotton—and fixes them before they become costly mistakes. We make sure your design not only looks great but also works well, wash after wash.

We are not just a supplier; we are a production partner focused on bringing your creative vision to life with care and quality. To ensure your project’s success from day one, partner with an expert manufacturer like ChengLin Clothing.

Ready to discuss your next collection?

- ● Direct Email: tesla@tuozhenclothing.com

- ● Phone Number: +8613713252727

- ● WhatsApp: +8613713252727

Conclusion: Making the Right Impression

An ideal Clothing screen printing process takes clothing design to the level of acquiring a piece of art that tells people about the person behind the clothing. It demonstrates first-hand your brand’s dedication to quality, meticulousness, and customer service.

The right one is always a thoughtful balance of your fabric, design vision, desired feel and budget. With these master techniques under your belt, you can then make reasoned decisions and appeal to your audience. The perfect print elevates an ordinary piece into a showstopper. We’re here to help you make it your own.

Real feedback from customers all over the world about ChengLin Manufacturer.

Communication & Production

How to Start Working with ChengLin Manufacturer?

3X

Your order is triple checked by our team prior to production and before shipment

Request a Free Quote & Consultation

Hit us up for a free quote. We’ll discuss your requirements — design, quantity, timing — and put a plan in place that works.

Submit Your Custom Design & Requirements

- Choosing Activewear Material

- Selecting the right Carft for the design

- Payment for samples

- Sample production after determining the color, size, and accessories of the sample

Receive Sample Prototypes for Approval

- Are the fabrics satisfactory?

- Does the craftsmanship live up to the design?

- Are there any changes that need to be made to the colors, sizes, and accessories?

- Details of large orders

Bulk Production & Delivery Process

- Payment of deposit for large orders

- Large Order Production Progress Inquiry

- Final payment upon completion of production

- Choose the right shipping method, pay the shipping fee, ship the goods

FAQ

What is the difference between screen printing and silk screen printing?

They are the same technique. The term “silk screen printing” originates from when screens were made from silk mesh, a technique with roots in ancient China.

Which screen printing technique is best for athletic wear?

Silicone 3D printing is ideal for athletic wear due to its extreme stretch, durability, and wash resistance – perfect for performance fabrics containing Lycra or Spandex.

How long does screen printed apparel typically last?

With proper techniques, screen printed apparel can last for years. Plastisol and Silicone 3D prints offer superior durability, while foil printing may require more gentle washing.

Can screen printing be done on dark-colored fabrics?

Yes! Techniques like rubber print, plastisol, and discharge printing work excellently on dark fabrics, with discharge actually removing the original dye to create a soft print.

Is water-based screen printing better for the environment?

Yes, water-based screen printing is more environmentally friendly than plastisol printing as it uses water instead of PVC-based chemicals, creating a softer, more breathable print.

ChengLin Manufacturer Offer

ChengLin Manufacturer was created to provide helpful service, simple streamlined ordering & eco-friendly options. A company with transparent prices & ethics, a company that aims to create good things.

ChengLin Activewear Manufacturer Difference

ChengLin was created, to provide helpful service, simple streamlined ordering & eco-friendly options. A company with transparent prices & ethics, a company who aims to create good things.

Innovative Ideas

ChengLin is proud to be a leading partner in the promotional products + fashion industry. With unique ideas + out of the box printing methods.

We Stand Behind Our Work

Our main goal is to provide peace of mind so you can relax and have confidence that your job will come out exactly as you had imagined.

Quality Over Quantity

ChengLin believes in quality over quantity and we want our customers to feel the same way.

Dedicated Reps

Each account receives a dedicated rep who can be reached face to face by phone or via e-mail.

Long Lasting Relationships

We value all of our clients and aim to solidify long lasting & mutually beneficial relationships.